Why the world’s biggest CO2-sucking plant would be used to … err, dig up more oil?

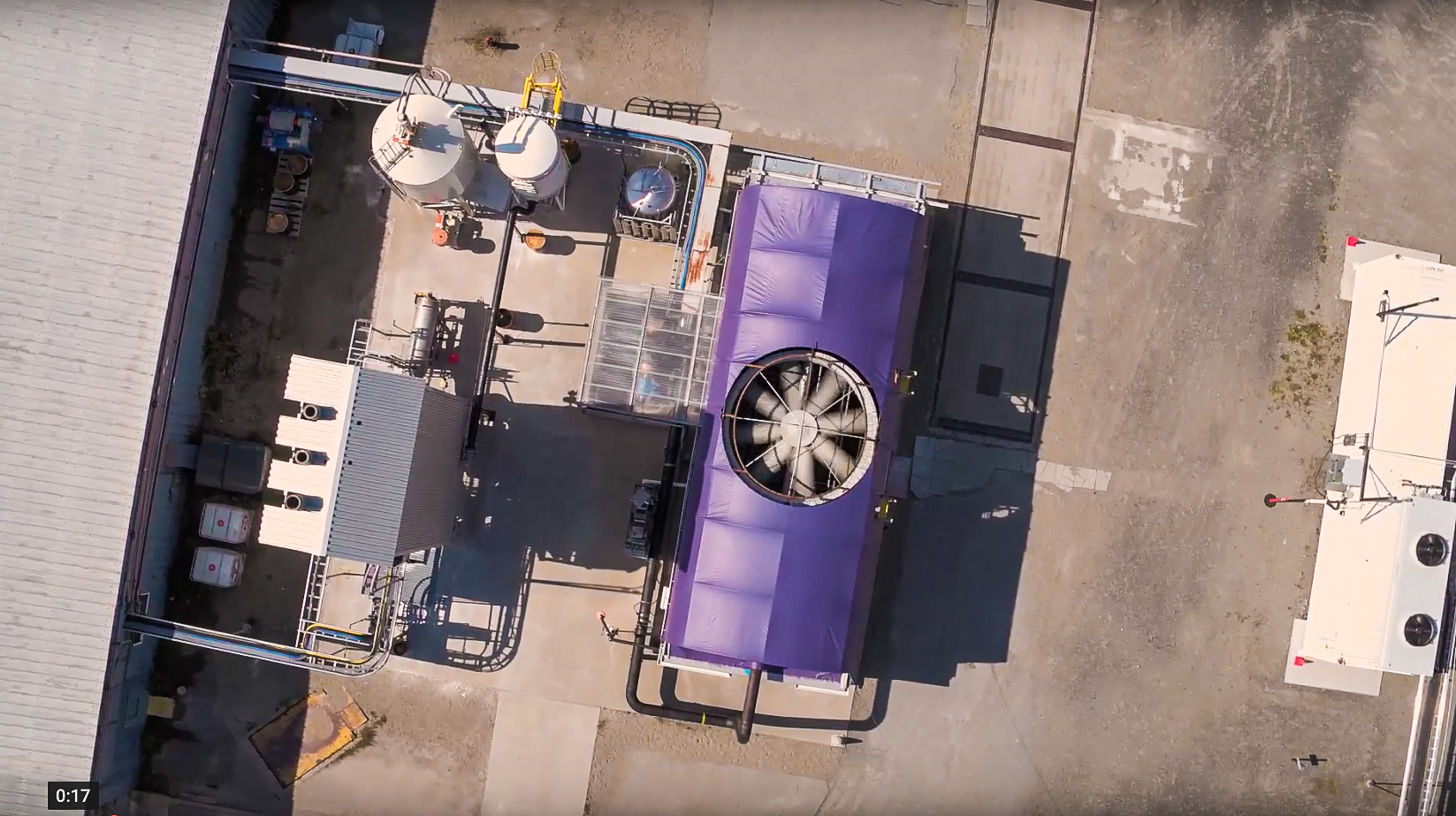

A Canadian startup plans to build the largest carbon dioxide removal plant in the world, capable of sucking half a million metric tons of the greenhouse gas out of the air every year.

If the project is ultimately built, it will represent a big step forward for direct air capture, a technology that a growing number of studies find could be essential for preventing dangerous levels of global warming. But it comes with a catch.

British Columbia–based Carbon Engineering is designing the Texas facility with a subsidiary of oil and gas giant Occidental, an investor in the direct air capture firm that would also be the main customer for the captured carbon dioxide. It would, in turn, inject carbon dioxide underground to free up additional oil from the company’s petroleum wells in the Permian Basin, in a process known as enhanced oil recovery.

Which poses an obvious question: Can producing more fossil fuel help combat climate change? Doesn’t that negate the whole point of pulling carbon dioxide out of the air in the first place?

“To the extent that you’re expanding the total energy resources base and extending the fossil-fuel era, obviously that doesn’t solve the climate problem.”

It’s at least “unambiguously better” than doing enhanced recovery the way it’s often done now, which involves first pulling up still more carbon dioxide from geological wells, says Dan Lashof, director of the World Resources Institute in the US.

Beyond that, enhanced oil recovery using captured carbon dioxide “opens a pathway to producing fully carbon-neutral or even net-negative fuels,” Richard Jackson, president of the subsidiary, Oxy Low Carbon Ventures, said in a statement.

All the carbon dioxide used in enhanced oil recovery can be permanently trapped in pores and fluids underground, though whether that happens depends on the geology of the site and how carefully the process is managed.

For the project to qualify as carbon neutral, Oxy would need to bury not just the same amount of CO2 released when the extracted oil is ultimately used, but an additional quantity sufficient to offset any emissions from its operations at the site as well as whatever amount was produced in the process of direct air capture.

For its part, Carbon Engineering hopes to operate the plant in a carbon-neutral way by capturing emissions from the natural gas used to power parts of the process, says Steve Oldham, chief executive of Carbon Engineering.

Why would a gas and oil company like Occidental be willing to deal with the headache of doing all this? Well, money.

The practice could enable the company to earn extra revenue, on top of the money from the fuel it sells, through several public policy mandates, including the “45Q” tax credit passed last year for burying carbon dioxide or putting it to use in other ways (see “The carbon-capture era may finally be starting”).

Oxy and Carbon Engineering could also earn money under California’s low-carbon fuel standard program. The program is designed to reduce the carbon intensity of transportation fuel sold in the state. But it also provides credits for emissions reductions achieved through direct air capture when carbon dioxide is sequestered in a way that complies with California’s standards, even if that process happens out of state. These credits can currently be sold for around $150 to $200 per ton.

Oxy hasn’t specified whether it intends to use the captured CO2 from the plant to produce carbon-neutral fuels some of the time, most of the time, or all of the time. It’s likely to depend on the geology and economics of each site. The company didn’t immediately respond to questions on this.

But the use of air capture for enhanced oil recovery still raises some real concerns.

Critics say the practice will help sustain an industry whose main goal will continue to be pulling fossil fuels out of the ground, inevitably undermining broader climate and environmental goals. In addition, it’s not clear whether the enhanced oil recovery operations enabled by such plants would replace other, dirtier recovery operations that would have happened anyway, or expand the total scope of such efforts. If it’s the latter, some worry it would increase supply and decrease prices, which could boost demand and overall emissions to some degree.

“It’s a lower-carbon source of oil than most other sources in the system,” Lashof says. “On the other hand, to the extent that you’re expanding the total energy resources base and extending the fossil-fuel era, obviously that doesn’t solve the climate problem.”

But the larger hope here is that by providing a profitable business path, enhanced oil recovery could help the direct air capture industry scale up, improve the technology, and drive down costs, says Deepika Nagabhushan, director of decarbonized fossil energy at the Clean Air Task Force. The grand dream is that eventually it will get cheap enough and there will be high enough prices on carbon, or other sufficiently strict policy mandates, for it to start making sense to simply bury the stuff underground on a massive scale.

An analysis by the Rhodium Group published earlier this month estimated that the US will need to have nine million tons of annual direct air capture capacity in place by 2030 to achieve necessary reductions by around midcentury. To pull that off, the research group recommends that the US government invest several billion dollars in research and development, enact a federal mandate for fuels derived from direct air capture, and increase the 45Q tax credit for buried CO2 from $50 a ton to $180, among other steps.

The Carbon Engineering project is in the engineering and design phase. If it’s ultimately approved, it would cost several hundred million dollars to build, which will require the company to raise additional funding, Oldham says. It’s undetermined at this point whether Oxy will contribute additional capital beyond its earlier investment in the company (see “Startups looking to suck CO2 from the air are suddenly luring big bucks”). Carbon Engineering expects that construction would begin in 2021 and take around two years.

The company hopes to eventually build additional facilities at the site capable of capturing a million tons of carbon dioxide. Carbon Engineering is pursuing other business models for the captured gas as well, including producing its own carbon-neutral synthetic fuels, or permanently sequestering the CO2 underground on behalf of companies or regions looking for ways to offset their emissions.

The Oxy deal provides the company with the business case it needs to raise the money to build out a large plant and demonstrate that the technology works at full scale, Oldham says.

“Then we’re ready to build as many plants as the world wants,” he says.

Deep Dive

Climate change and energy

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Harvard has halted its long-planned atmospheric geoengineering experiment

The decision follows years of controversy and the departure of one of the program’s key researchers.

Decarbonizing production of energy is a quick win

Clean technologies, including carbon management platforms, enable the global energy industry to play a crucial role in the transition to net zero.

How thermal batteries are heating up energy storage

The systems, which can store clean energy as heat, were chosen by readers as the 11th Breakthrough Technology of 2024.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.