A nanotube material conducts heat in just one direction

Heat is something of a nuisance for electrical engineers. It reduces the reliability of electronic devices and even causes them to fail completely. That’s why computer components are liberally smeared with thermal paste and connected to heat pipes, fans, and even water cooling systems.

The goal is to channel the heat away from sensitive components so that it can dissipate into the environment. But as devices get smaller, the challenge becomes more acute—and modern transistors, for example, are measured in nanometers.

The most cost-efficient conductors are metals such as copper, but heat travels through them equally well in all directions. That means heat can spread to any other component that is also in thermal contact with the metal.

A more effective conductor would channel heat in one direction but not in the perpendicular one. In this case, heat would travel along such a material but not across it.

This kind of asymmetric conductor would make the life of thermal engineers significantly easier. But creating them is hard.

Enter Shingi Yamaguchi at the University of Tokyo in Japan and a group of colleagues, who have created a material out of carefully aligned carbon nanotubes that conducts heat in just this way. The new substance has the potential to revolutionize the way thermal engineers design and build cooling systems for computers and other devices.

First some background. Materials scientists are well aware that carbon nanotubes are exceptional conductors. These tiny tubes have a thermal conductance in excess of 1,000 W m-1 K-1. By comparison, copper has a thermal conductance of about 400 W m-1 K-1.

The trouble arises when materials scientists try to make a bulk material out of nanotubes. They do this by allowing the tubes to settle on a plastic substrate, forming a layer. But the nanotubes tend to be poorly aligned or randomly arranged.

As a result, they are in poor thermal contact with each other, and this reduces the conductivity of the bulk material. “It is essential to eliminate these structural deficiencies to utilize the high thermal conductance of individual carbon nanotubes in aligned carbon nanotube assemblies,” says Yamaguchi and co.

Their solution is simple: they create a material in which the carbon nanotubes are precisely aligned and are therefore in good end-to-end thermal contact.

This is possible thanks to a technique known as controlled vacuum filtration. Back in 2012, physicists discovered that in certain circumstances, floating carbon nanotubes can form a self-organized structure in which they all become aligned as in a crystal.

The nanotubes are first mixed together in a liquid containing a surfactant that reduces its surface tension. Provided the concentration of nanotubes is below some critical level, they then begin to self-organize on the surface of the liquid and become densely aligned.

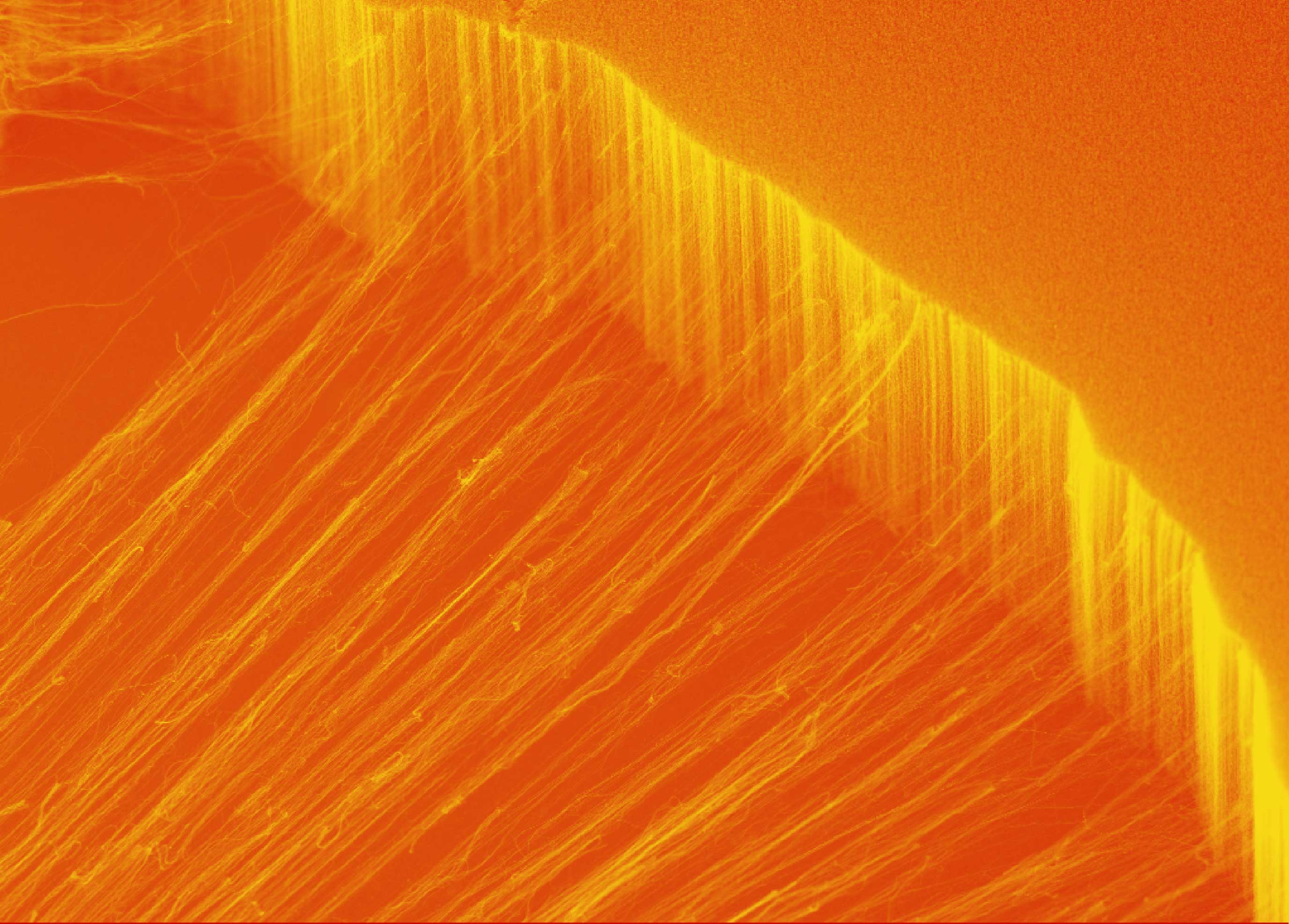

The liquid is then removed by carefully and slowly sucking it through a filter using a vacuum, leaving the nanotubes behind. The result is a thin sheet of highly aligned nanotubes with some extraordinary properties.

Yamaguchi and co say the new material conducts heat in the direction of nanotube alignment with a thermal conductance of 43 W m-1 K-1. By contrast, the conductance in the perpendicular direction is three orders of magnitude smaller at 0.085 W m-1 K-1, about the same as fiberglass.

In other words, the material is 500 times better at conducting in one direction than in the other—the greatest asymmetry ever observed for these kinds of materials.

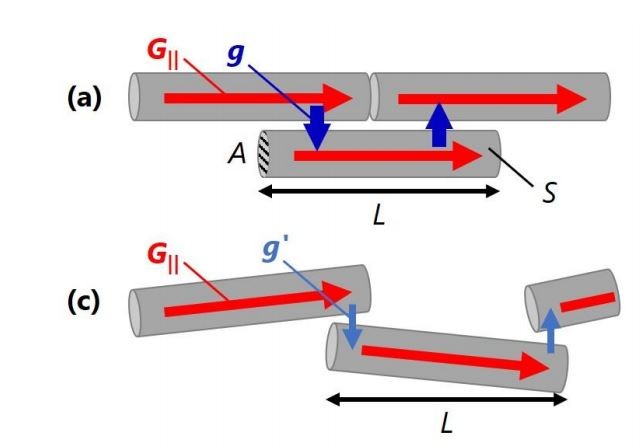

The reason is simple. When the nanotubes are in thermal contact from end to end, heat travels easily from one to another. But the tubes are not in good thermal contact along their length, since the contact footprint is tiny for tubes next to each other.

Yamaguchi and co are quick to point out the limitations of their new material. Although it has hugely asymmetric properties, its highest thermal conductivity is just 43 W m-1 K-1, about the same as tin/lead solder.

However, they think they know why it is so low compared with that of single carbon nanotubes. They say that although the nanotubes are in thermal contact from end to end, this contact is not perfect. Each jump that the heat has to make from one nanotube to the next reduces the thermal conductance. And the shorter the tubes, the more jumps are required.

Yamaguchi and co use nanotubes that are just 200 nanometers long. “This suggests that the [thermal conductance in the direction of nanotube alignment] can be even greater with longer constituent carbon nanotubes,” they say.

Making a similar material out of longer nanotubes will not necessarily be straightforward. The self-organizing behavior that creates the aligned films is more difficult for longer nanotubes. But this kind of materials science challenge will surely interest Yamaguchi and co and others. No doubt the experiments are already under way, with thermal engineers keeping their fingers crossed.

Ref: arxiv.org/abs/1911.11340 : One-Directional Thermal Transport In Densely Aligned Single-Wall Carbon Nanotube Films

Deep Dive

Computing

How ASML took over the chipmaking chessboard

MIT Technology Review sat down with outgoing CTO Martin van den Brink to talk about the company’s rise to dominance and the life and death of Moore’s Law.

Why it’s so hard for China’s chip industry to become self-sufficient

Chip companies from the US and China are developing new materials to reduce reliance on a Japanese monopoly. It won’t be easy.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.