Ceramic Pump That Takes the Heat Promises Cheap, Efficient Grid Storage

Scientists have developed a ceramic pump that can operate at 1,400 ˚C, several hundred degrees hotter than existing heat transfer systems, opening up significant new possibilities for energy storage.

Specifically, the authors of the new study, published in the journal Nature on Wednesday, believe it could be used to develop an efficient grid storage system that could eventually help make renewable sources like wind and solar as cheap and reliable as natural-gas plants (see “Serial Battery Entrepreneur’s New Venture Tackles Clean Energy’s Biggest Problem”).

The thermal storage system in question would use liquid metals like molten silicon, which would enable the storage and transfer of heat energy at far higher temperatures than materials typically used, such as molten salts. Higher temperatures mean that more thermal energy can be converted to mechanical or electrical energy, improving overall efficiency.

“This is enabling us to now move heat around at extremely high temperatures,” says Asegun Henry, an assistant professor at the Georgia Institute of Technology. “It’s a step change in terms of what you can do.”

Interest in using liquid metals as a heat storage medium has been growing, but the challenge has been developing pumps and pipes that don’t deteriorate under such conditions. Ceramics can withstand incredibly high temperatures, but they’re also brittle, which makes them difficult materials for creating machine components.

The researchers at Georgia Tech, along with collaborators at Stanford and Purdue, got around this limitation by taking advantage of new composite materials, along with diamond tooling and precision machining. They also employed seals made from graphite, another material that stands up to very high temperatures.

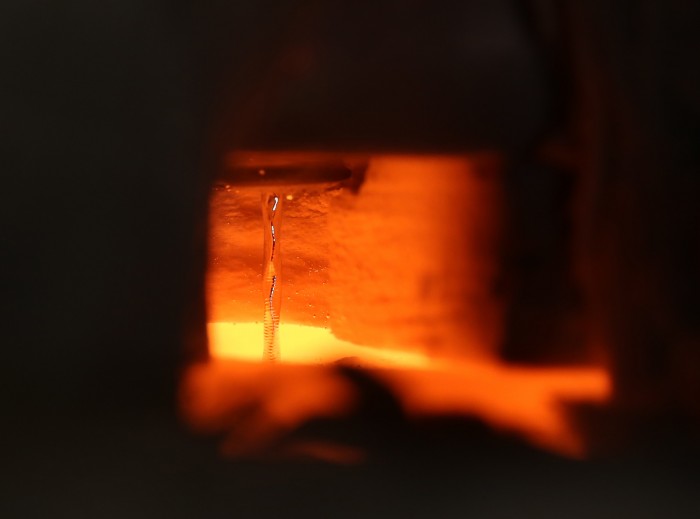

The prototype mechanical pump successfully operated for 72 hours straight using molten tin, at average temperatures of around 1,200 ˚C and a peak temperature of 1,400 ˚C. The pump did show signs of wear after the tests. But as a next research step, the scientists are developing a pump made from silicon carbide, a harder ceramic material that should be able to last much longer.

The research was backed by $3.6 million in funding from ARPA-E, the U.S. Department of Energy’s moonshot energy research division.

The proposed grid storage system would use electricity from solar, wind, or nuclear power to heat liquid silicon to very high temperatures, creating thermal energy. At times of high demand and low energy production, such as evenings after the sun has gone down, the system would return that energy back to the grid using thermophotovoltaics, a type of cell that can convert heat in the form of infrared light into electricity (see “Hot Solar Cells”).

The so-called thermal energy grid storage (TEGS) system would work just as well with coal or natural gas. But the promise here is that the technology could offer a form of cheap baseload storage for renewables, storing up enough energy when the sun is shining and wind is blowing to continue producing electricity even when they’re not.

To date, the contribution that clean energy sources can make has been limited by the high cost of battery systems and the restricted geography of storage systems like pumped hydroelectric.

The liquid metals that the high-temperature pump makes usable have other potential applications as well. They might replace molten salts in concentrated solar power systems, and they could enable new kinds of metal-cooled nuclear reactors (see “Making Sense of Trump’s Surprising Investment in Solar”).

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.