New 3-D Printing Technique Makes Ceramic Parts

Ceramics are some of the hardest materials on Earth. They can withstand extreme temperatures, and some are impervious to friction, scratching, and other mechanical stresses that wear out metal and plastic. But it can be difficult to make complex shapes out of the materials.

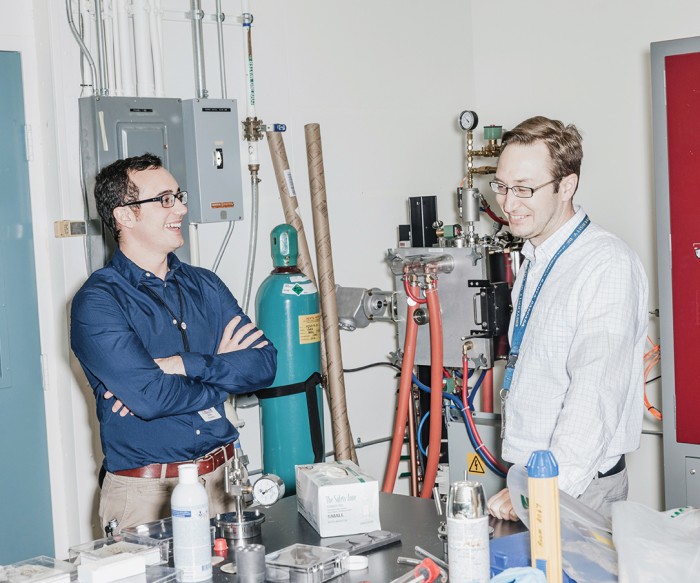

Chemists at HRL Laboratories in Malibu, California, may have gotten around that problem by developing ceramics that can be made in a 3-D printer. The result: ultrastrong objects that are impossible to make using conventional methods.

Ceramics are used today in brake pads, the housing of microelectronics, and thermal shielding tiles (like the ones on spacecraft). Now the scientists at HRL are trying to substantially expand the applications. If parts for aircraft engines were made of ceramic, for example, the engines could run at a higher temperature, increasing their efficiency.

Ceramics could also offer an upgrade on parts used in steam turbines and other machines that must withstand searing, mechanically harsh conditions. The lab is co-owned by Boeing and General Motors, and the project has some funding from DARPA, the R&D arm of the U.S. Department of Defense.

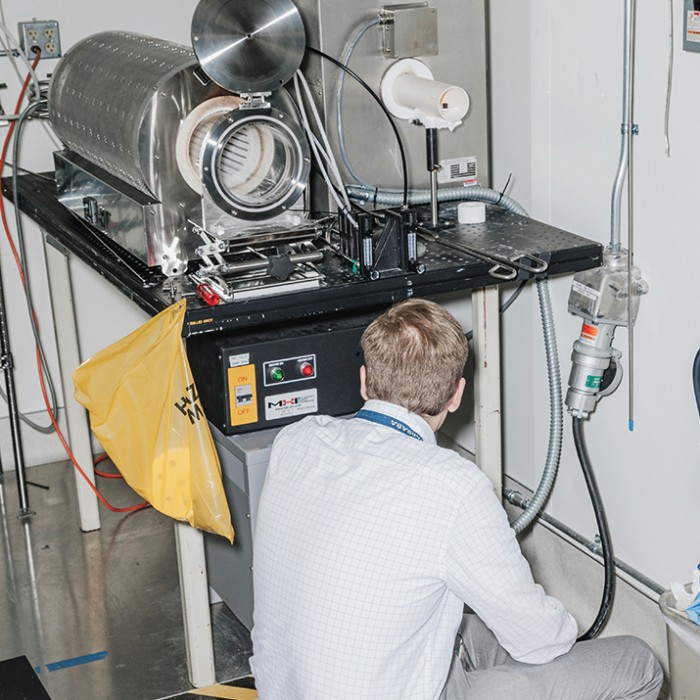

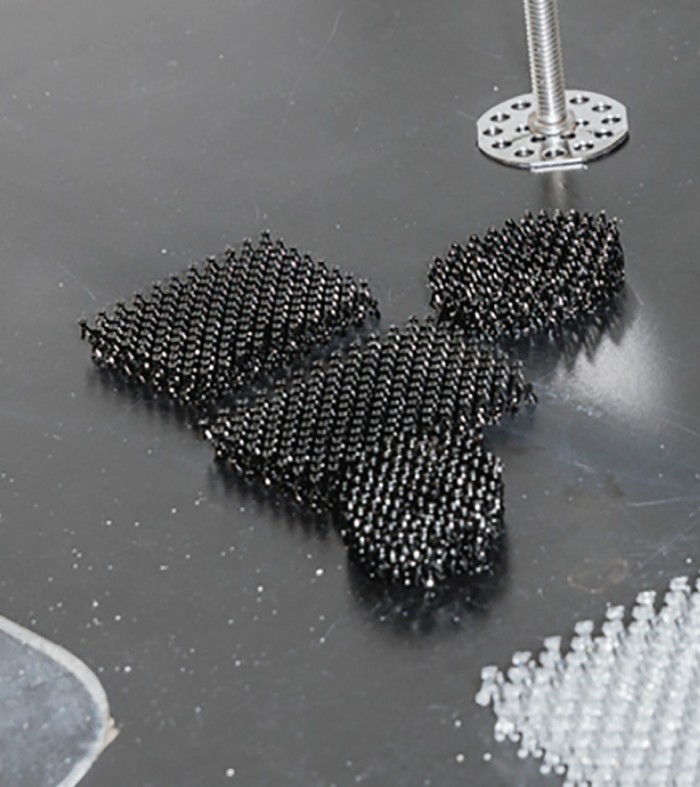

HRL’s trick is to formulate special resins that can be used as the ink in a printer. They are made out of polymers but carry in their molecular structure silicon and other elements found in ceramics. These resins are loaded into 3-D printers to make parts with baroque shapes, such as corkscrews and sheets of intricate lattices. Then those parts go into a furnace to bake out the organic polymer components, leaving behind ceramic material.

The 3-D-printed ceramics could be better in some respects than their conventional counterparts. One lattice made at HRL has 10 times the compressive strength of commercially available ceramics. These printed parts can also tolerate heats as high as 1,700 °C, a temperature at which other ceramics start to degrade.

But the group still hopes to make its printed ceramics stronger. One approach is to design new kinds of pre-ceramic polymers that have fibers embedded in them to stop cracks from spreading. Ceramics are brittle and can fail catastrophically with one crack. It wouldn’t do if a minuscule defect caused a clever new part to shatter.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.