Moon-Landing Equivalent for Robots: Assembling an IKEA Chair

Humans have long feared that robots are taking over the world. The truth, however, is more prosaic. It’s certainly the case that robots have revolutionized certain tasks such as car manufacturing, for example.

But in many real world tasks, robots come a poor second to humans. They find it impossible to work in the messy, cluttered environment that humans cope with easily. They have difficulty locating and picking up small objects and they lack the fine control to assemble components.

All these problems are exemplified in a single task—the assembly of an IKEA chair. This is an activity that many humans will have performed with varying degrees of success but one that robots simply cannot complete. At least not yet.

Now Francisco Suarez-Ruiz and Quang-Cuong Pham at the Nanyang Technological University in Singapore, have set themselves the goal of assembling an IKEA chair using a robot. And today, they reveal the progress they have made. Their robot isn’t quite capable of completing the entire task but it has taken significant steps in that direction.

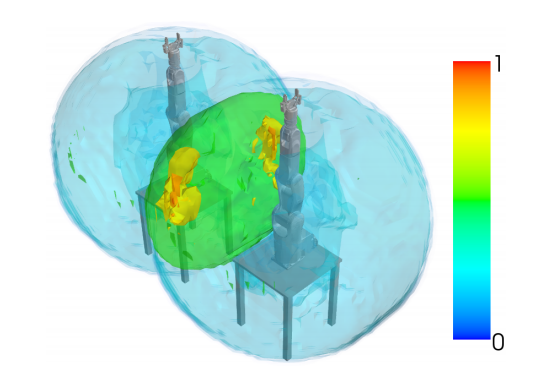

The robot in question consists of two arms capable of six-axis motion, each equipped with parallel grippers to pick up objects. These grippers cannot manipulate objects “in-hand” once they are picked up. However, they are common in industry so any lessons that Suarez-Ruiz and Pham learn will be widely applicable.

The grippers also have force sensors to determine how strongly they are gripping and how powerfully they push objects into contact with each other. The robot also has a vision system consisting of six cameras that can track up to five objects with a positional accuracy of around three millimeters.

That’s an impressive piece of kit but it comes up against a formidable adversary in the form of an IKEA chair.

Suarez-Ruiz and Pham have broken down the job of assembly into various sub tasks. One of these is the insertion of a small wooden cylinder, a dowel, into a hole in another stick of wood.

This activity itself is made up of three tasks. First, one arm has to locate and pick up the dowel. Second, the other arm has to locate and pick up the wooden stick. Finally, the robot has to locate the hole and insert the dowel into it.

That robot immediately runs into a number of problems. The first is that the dowel is only a few millimeters in size and so close to the vision system’s limit of positional accuracy.

Suarez-Ruiz and Pham solve this with a protocol in which the robot places the parallel grippers near the dowel, while “feeling” that it is in contact with the table. It then closes its grip slowly to grasp the dowel.

The stick is easier to grasp. But the hole within it is hard to locate because it too is at the boundary of what the vision the system can detect.

Suarez-Ruiz and Pham have another protocol to solve this. The robot places the dowel on the stick near the hole and performs a pre-programmed sequence of motions to map out the shape of the surface and its edges using its force sensors. It then explores the surface near the hole by pushing the dowel gently against the surface until it enters the hole.

And that’s it—the first successful robotic insertion of a wooden dowel into a hole in something like real world conditions. Suarez-Ruiz and Pham have posted a video of their robot in action here.

That’s an important step toward the deceptively difficult task of assembling an IKEA chair. And the duo is determined to go further. “This work will continue until completion of all the tasks required for assembling an IKEA chair,” they say.

Of course, the conditions aren’t quite what most humans have to cope with. The parts are clearly visible on a white table under good lights, rather than strewn on the floor in a poorly lit attic surrounded by cardboard packaging. Neither are there other distractions such as missing parts, know-it-all “helpers” or screaming kids in background.

But perhaps the biggest problem is that this system cannot interact with humans, who have to be kept away entirely lest the robot injure them. That’s a problem that other groups are beginning to deal with.

Perhaps together, these groups will come up with a machine that can successfully complete tasks that require fine motor control, under a wide range of real world conditions without injuring the humans around them. In many ways, this goal is the equivalent of the moon landings for robotics—it is an extremely difficult, but easily imagined task that could have a huge impact on humankind.

For when that happens, robots really will have become useful household appliances that may well take over some aspects of our world.

Ref: arxiv.org/abs/1509.04806 : A Framework for Fine Robotic Assembly

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.