“Nanobuds” Could Turn Almost Any Surface into a Touch Sensor

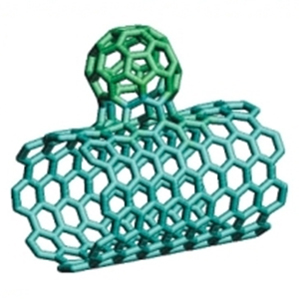

Transparent films containing carbon nanobuds—molecular tubes of carbon with ball-like appendages—could turn just about any surface, regardless of its shape, into a touch sensor.

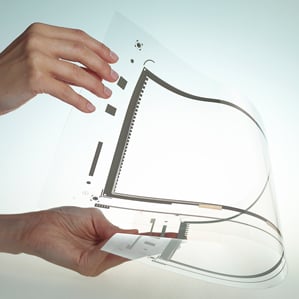

The films were developed by a Finnish startup, Canatu, and could be used to add touch controls to curved automobile consoles and dashboards, for example. The films are rugged and can be repeatedly bent around something as thin as the cord for your earbuds, so they could be handy for adding buttons to flexible devices.

Touch screens are usually made by overlaying a display screen with a transparent sheet of indium tin oxide. This material is brittle, however, and can’t be used on anything other than a flat surface. Individual carbon nanotubes have long been seen as a promising alternative because they conduct electricity so well. But carbon nanotubes have performed badly in touch screens due to poor electrical connections between different nanotubes. Carbon nanobuds are better because the ball-like appendages are particularly good at emitting electrons, which improves those electrical connections.

Canatu has 40 prototype products in the works. It recently built its first full-scale manufacturing equipment, which can produce enough film to cover hundreds of thousands of smartphone touch screens every month. Next year the company plans to install enough machines to supply millions of smartphones.

Films containing carbon nanotubes have previously been too expensive to produce commercially. Canatu’s founders, researchers at Aalto University, in Finland, improved the electrical connections between carbon nanotubes by modifying their shape, and also found a way to make nanobud films cheaply.

Making carbon nanotubes films conventionally is a complex process that requires costly purification steps that can sometimes damage the nanotubes. Canatu’s manufacturing approach starts with carbon-containing gases, which are converted directly into nanobuds and deposited to make a transparent film in one step, without the need for purification.

The material isn’t a good fit for all applications, though. The conductivity isn’t high enough for very large screens, for example.

But the nanobud films can stretch over a surface, says Erkki Soininen, vice president of marketing and sales, sometimes by more than 200 percent without losing much performance. Most other stretchable touch screens stretch by only a few percent. The material stretches because the carbon nanobuds are able to slide past one another while maintaining good electrical contact.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.