Self-Healing Metals

When graduate student Guoqiang Xu and assistant professor of materials science and engineering Michael Demkowicz, SM ’04, PhD ’05, first saw the result, they thought it must be a mistake. Under certain conditions, they found, putting a cracked piece of metal under tension—that is, exerting a force that would be expected to pull it apart—had the reverse effect, causing the crack to close and its edges to fuse together. The finding, they say, could lead to self-healing materials that repair incipient damage before it has a chance to spread.

They “had to go back and check,” Demkowicz says, when “instead of extending, [the crack] was closing up. The next question was: ‘Why is this happening?’”

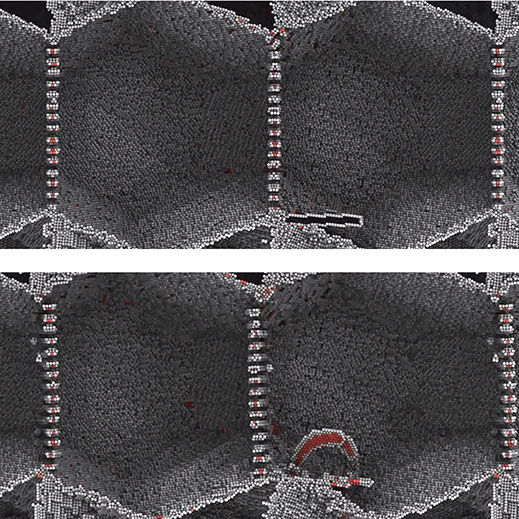

The answer turned out to lie in the crystalline microstructure of a metal—in this case nickel, which is the basis for “superalloys” used in extreme environments such as deep-sea oil wells. By creating a computer model of nickel’s microstructure and studying its response to various conditions, Demkowicz says, “we found that there is a mechanism that can, in principle, close cracks under any applied stress.”

Metals tend to be made up of tiny crystal grains—regions where the atoms are lined up in a precisely ordered way. At the boundaries between these grains, the orientation of that pattern may change abruptly. Under certain conditions, Demkowicz and Xu found, stress causes the microstructure to change, making grain boundaries migrate, they say. In effect, one grain grows while the adjacent one shrinks. “This grain boundary migration is the key to healing the crack,” Demkowicz says.

Self-healing occurs only in metals containing a certain kind of boundary, he explains—one that extends partway through a grain but not all the way across it. This creates a type of defect known as a “disclination.”

These defects have intense stress fields, which “can be so strong they actually reverse what an applied load would do,” Demkowicz says. So when the two sides of a cracked material are pulled apart, instead of cracking further, it can heal. “The stress from the disclinations is leading to this unexpected behavior,” he says.

Having discovered this mechanism, the researchers plan to study how to design metal alloys so cracks would close and heal under loads typical of particular applications. Techniques for controlling the microstructure of alloys already exist, Demkowicz says, so it’s just a matter of figuring out how to achieve a desired result.

“That’s a field we’re just opening up,” he says. “How do you design a microstructure to self-heal? This is very new.”

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.