A Battery That Stretches to Three Times Its Size

Flexible, stretchable electronic devices will help monitor athletes on the field, take medical monitoring away from the hospital bedside, and make portable electronics more comfortable—perhaps even wearable. But to do anything at all, they need a power source. Now researchers have demonstrated a rechargeable lithium-ion battery that can be stretched by as much as 300 percent.

Since 2011, researchers led by John Rogers, a materials scientist at the University of Illinois at Urbana-Champaign, have demonstrated stretchable versions of just about every electronic component—circuits, sensors, electrodes, light-emitting diode arrays, and more. Rogers’s goal, in his lab and at his startup company, MC10 of Cambridge, Massachusetts, is to make high-performance, comfortable, wearable health monitors. These electronics devices might go on clothing, attach directly to the skin in the form of a temporary tattoo, or even fit inside the body, for example on the surface of the beating heart. For all such applications, stretchiness is vital.

The challenge is that the best performing electronic devices, including silicon transistors, aren’t stretchable. The Illinois researchers have overcome this problem for some components by making them very thin and integrating them into large, widely spaced arrays built on stretchable substrates, such as thin sheets of silicone.

However, this approach won’t work for a battery, says Rogers’s collaborator Yonggang Huang, a mechanical engineer at Northwestern University in Evanston, Illinois. The active materials in a battery have to be densely packed, or the battery will store very little energy in a given volume, and it won’t last long between charges.

The solution devised by Rogers and Huang was to make a dense array of lithium-ion battery cells on a stretchable material, and wire them together with compact, yet highly extensible wires. These connections take up a very small area of the array, leaving more room for energy-storing materials. But they’re packed into dense serpentine squiggles that buckle, then unravel as the battery is stretched. Huang used mathematical modeling to design the packed-wire geometry. “We wanted to fill that space with as much wire as possible,” he says.

As the sheet of battery cells is stretched to as much as 300 percent of its original area, the batteries themselves remain islands of mechanical stability, while the interconnects take the strain. “That’s a pretty impressive level of stretchability,” says Yi Cui, a materials scientist at Stanford University who is also developing stretchable energy storage devices. Previous stretchy batteries can only go to about 150 percent.

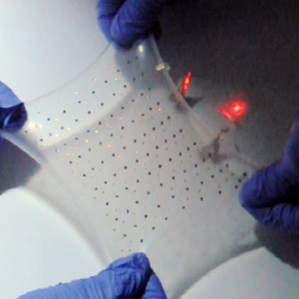

The Illinois group demonstrated that the battery could operate an LED even while being stretched. And they demonstrated that the battery could be charged without the need to plug it into the wall—an inconvenience for electronics worn on the clothes, and an impossibility for implanted electronics—by pairing it with a similarly stretchy sheet of resonators that can be used to wirelessly recharge the battery. The Illinois group also showed that the battery can take the strain when wrapped around a person’s elbow and flexed. This work is described in the online journal Nature Communications.

Daniel Steingart, a mechanical engineer at Princeton University who was not involved with the work but who is also developing stretchable power sources, says the batteries put out enough power to run sensors and processors. However, he says, the batteries will have to be even more densely packed to be truly useful.

Huang says his group is now working on improving the batteries’ performance. So far, they’ve only demonstrated 20 charge cycles—that means they don’t know for certain whether the batteries will last after they’ve been discharged and recharged more than 20 times. He’s also continuing to model the geometry of the wires in the hopes of packing the batteries more densely.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.