High-Res 3-D Imaging on the Go

By combining a clever physical interface with computer-vision algorithms, researchers in MIT’s Department of Brain and Cognitive Sciences have created a simple portable imaging system that can achieve resolutions previously possible only with large and expensive lab equipment. The device could provide manufacturers with a way to inspect products too large to fit under a microscope and could have applications in medicine, forensics, and biometrics.

The heart of the system, dubbed GelSight, is a transparent slab of synthetic rubber, one of whose sides is coated with a paint containing tiny flecks of metal. When pressed against the surface of an object, the paint-coated side of the slab deforms. Cameras mounted on the other side of the slab photograph the results, and computer-vision algorithms analyze the images.

Although GelSight’s design is simple, it addresses a fundamental difficulty in 3-D sensing. Micah Kimo Johnson, a former postdoc in the laboratory of BCS professor Edward Adelson, illustrates the problem with a magnified photograph of an emery board, whose surface, in close-up, looks a lot like marmalade—a seemingly gelatinous combination of reds and oranges.

“The optical property of the material is making it very complicated to see the surface structure,” Johnson says. “The light is interacting with the material. It’s going through it, because the crystals are transparent, but it’s also reflecting off of it.”

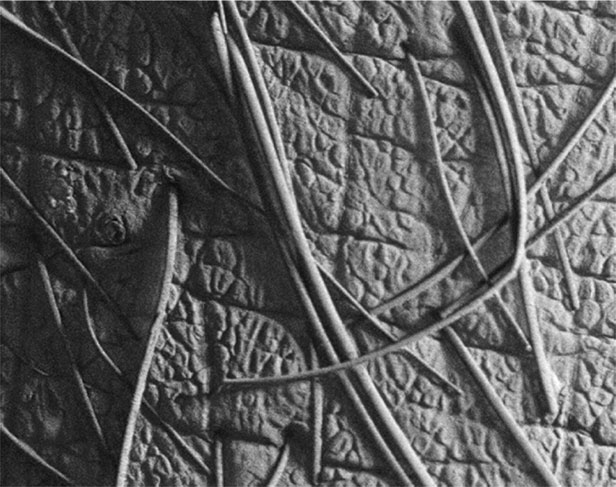

When a surface is pressed into the GelSight gel, however, the metallic paint conforms to its shape, making the optical properties of the surface perfectly uniform. “Now the surface structure is more readily visible, but it’s also measurable using some fairly standard computer-vision techniques,” Johnson explains.

GelSight is able to register physical features less than a micrometer in depth and about two micrometers across. Moreover, because it makes multiple measurements of the rubber’s deformation, with light coming in at several different angles, it can also produce 3-D models of an object. The prototype sensor is about the size of a soda can and can produce micrometer-scale 3-D images in almost no time, compared with minutes or even hours for conventional equipment.

Adelson and Johnson are already in discussion with a major aerospace company and several manufacturers of industrial equipment, all of whom are interested in using GelSight to check the integrity of their products.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.