Shapes With "Capillary Charges" Self Assemble on the Surface of Liquids

“Capillary charges”, which act like magnetic poles on the surface of liquids, can pull millimetre-sized building blocks together, a technique that promises a new era of mesoscopic-scale manufacturing.

When a liquid comes into contact with a solid, the liquid surface deforms because of forces between the different molecules involved. These so-called capillary forces can lift the liquid at the interface or depress it. Much depends on the intramolecular forces involved but the shape of the solid also plays a role.

These forces lead to important and familiar phenomena. The process of wicking is one, where a liquid is drawn up a narrow tube against gravity. This is one of the main processes by which trees and plants draw water out of the ground.

But there are less well known applications too. One idea is to use capillary forces to make floating particles self-assemble into bigger, more complex shapes.

This story is only available to subscribers.

Don’t settle for half the story.

Get paywall-free access to technology news for the here and now.

Subscribe now

Already a subscriber?

Sign in

You’ve read all your free stories.

MIT Technology Review provides an

intelligent and independent filter for the

flood of information about technology.

Subscribe now

Already a subscriber?

Sign in

Today, Nicolas Vandewalle and pals at the Université of Liège in Belgium have developed an entirely new way to manipulate capillary forces for self-assembling structures. The trick these guys have perfected is to create both attractive and repulsive forces by carefully controlling the shape of the particles they want to assemble. “Our method is based on the creation of capillary multipoles inducing either attractive or repulsive forces,” they say.

One way to create both attractive and repulsive forces is to cover the building blocks with hydrophobic or hydrophilic coatings. This creates different capillary ‘charges’. And since opposite charges attract while similar charges repel, this can be exploited during self-assembly.

But that’s a time consuming business, particularly when different parts of the same building block must be attractive and repulsive and requires different coatings.

Much easier would be a way to manufacture the building blocks in a single step with the required capillary charges. And that’s exactly what Vandewalle and co have done.

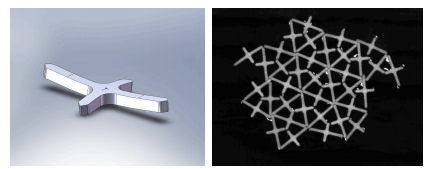

These guys show how bending the building blocks, so that they are no longer flat relative to the liquid surface, can induce different capillary charges.

And they’ve used a 3D printer to make building blocks a few millimetres in size in the necessary shapes to create capillary multipoles. They’ve then observed how they assemble when floated on water.

The technique is simple. Having designed and printed the building blocks, they place them on a wire mesh, arranged at random, and then slowly lower it into tank of water. They then observe the building blocks as they float on the surface and coalesce.

The results are interesting. They clearly show how the specially engineered building blocks assemble into large scale shapes that preserve the symmetry of the individual building blocks. Indeed, in one example, 35 building blocks assemble into a perfect pentagon. “This work opens new perspectives in self-assembly,” say Vandewalle and co.

And they say that combining the technique with magnets could allow the self-assembly of 3D shapes.

That’s a potentially important advance for mesoscopic assembly. And the building blocks can be made considerably smaller, since capillary forces act at scales down to the micrometre range.

Vandewalle and co do not discuss how they intend to use this new technique, which gives Technology Review readers the perfect excuse to step in with some ideas of their own. Suggestions in the comments section below, please.

Ref: arxiv.org/abs/1310.4847: Customizing Mesoscale Self-Assembly With 3D Printing