Want to take a solar cell to a remote location so you can easily charge your flashlight or your cell phone? No problem: fold it up and slip it into your back pocket.

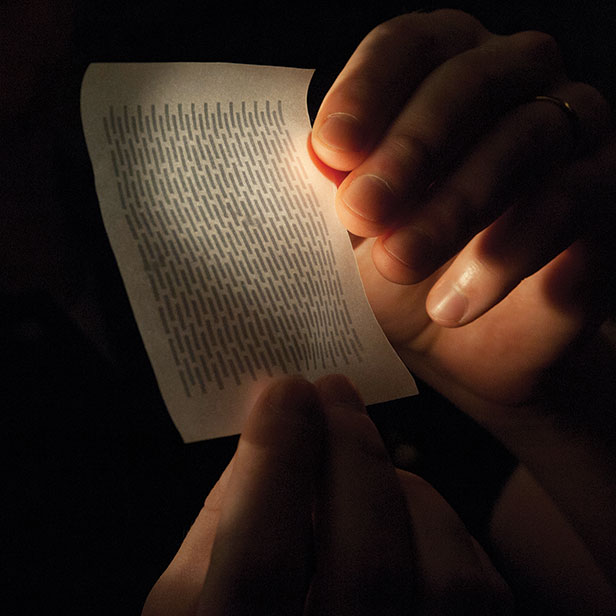

That’s the promise of a new technology developed by MIT professors Karen Gleason ‘82, SM ‘82, and Vladimir Bulovi, working with graduate student Miles Barr and several other students and postdocs. They have developed a way to print a solar cell onto almost any material, including flexible plastics, cloth, and paper. In tests, the new photovoltaic material showed virtually no loss of performance after being folded and unfolded 1,000 times.

In the United States, a solar cell’s supporting structure, the installation process, and the substrate (usually glass) that holds the photovoltaic material can cost up to twice as much as the active components of the cell itself. Printing solar cells directly onto inexpensive materials and then just fastening them to a wall for support could drastically reduce the costs of solar installations, which could be incorporated into window shades or wallpaper. Today, most commercial photovoltaic cells are produced using very high temperatures. The printing process developed by the MIT team requires temperatures of less than 120 °C, making it possible to use untreated cloth, plastic, or even ordinary paper as a substrate. The process also has an advantage over recently developed methods that print solar cells by using liquids to deposit organic materials onto a substrate. While printing with liquids can leave gaps on rough surfaces, hindering the device’s electrical conductivity, Gleason and Bulovi’s process uses vapors instead of liquids, producing a more uniform layer, even on rough surfaces like paper. And paper costs a thousandth as much as glass for a given area, the researchers say.

Don’t settle for half the story.

Get paywall-free access to technology news for the here and now.