Ultra-Efficient Solar

This past winter, a startup called Semprius set an important record for solar energy: it showed that its solar panels can convert nearly 34 percent of the light that hits them into electricity. Semprius says its technology, once scaled up, is so efficient that in some places, it could soon make electricity cheaply enough to compete with power plants fueled by coal and natural gas.

Because solar installations have many fixed costs, including real estate for the arrays of panels, it is important to maximize the efficiency of each panel in order to bring down the price of solar energy. Companies are trying a variety of ways to do that, including using materials other than silicon, the most common semiconductor in solar panels today.

For example, a startup called Alta Devices (see the TR50, March/April 2012) makes flexible sheets of solar cells out of a highly efficient material called gallium arsenide. Semprius also uses gallium arsenide, which is better than silicon at turning light into electricity (the record efficiency measured in a silicon solar panel is about 23 percent). But gallium arsenide is also far more expensive, so Semprius is trying to make up for the cost in several ways.

A new mass-production process makes high-efficiency gallium arsenide a more cost-effective photovoltaic material.

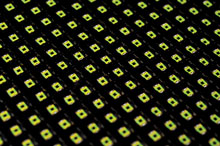

One is by shrinking its solar cells, the individual light absorbers in a solar panel, to just 600 micrometers wide, 600 micrometers long, and 10 micrometers thick. Its manufacturing process is built on research by cofounder John Rogers, a professor of chemistry and engineering at the University of Illinois, who figured out a way to grow the small cells on a gallium arsenide wafer, lift them off quickly, and then reuse the wafer to make more cells. Once the cells are laid down, Semprius maximizes their power production by putting them under glass lenses that concentrate sunlight about 1,100 times.

Concentrating sunlight on solar panels is not new, but with larger silicon cells, a cooling system typically must be used to conduct away the heat that this generates. Semprius’s small cells produce so little heat that they don’t require cooling, which further brings down the cost. Scott Burroughs, Semprius’s vice president of technology, says utilities that use its system should be able to produce electricity at around eight cents per kilowatt-hour in a few years. That’s less than the U.S. average retail price for electricity, which was about 10 cents per kilowatt-hour in 2011, according to the U.S. Energy Information Administration.

The gallium arsenide is the black square on each cell. Using such small amounts of the expensive material keeps costs down.

Semprius’s advantages are tempered by the limitations of using lenses to concentrate light: the system works best when the cells receive direct sunlight under a cloudless sky, and energy production drops significantly under any other conditions. Even so, it could be suitable for large, utility-scale projects in places such as the American Southwest.

First, however, Semprius has to begin mass-producing its panels. The company, which has raised about $44 million from venture capital firms and Siemens (which builds solar power plants), plans this year to open a small factory in North Carolina that can make enough solar panels annually to deliver six megawatts of electricity. The company hopes to expand that to 30 megawatts by the end of 2013, but to do so it must raise an undisclosed amount of money in an atmosphere that is no longer kind to capital-intensive energy startups.

All the while, Semprius will also have to reduce its manufacturing costs fast enough to compete with conventional silicon panels, whose prices fell by more than half in 2011 alone.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.