Paper Diagnostics

Diagnostic tools that are cheap to make, simple to use, and rugged enough for rural areas could save thousands of lives in poor parts of the world. To make such devices, Harvard University professor George Whitesides is coupling advanced microfluidics with one of humankind’s oldest technologies: paper. The result is a versatile, disposable test that can check a tiny amount of urine or blood for evidence of infectious diseases or chronic conditions.

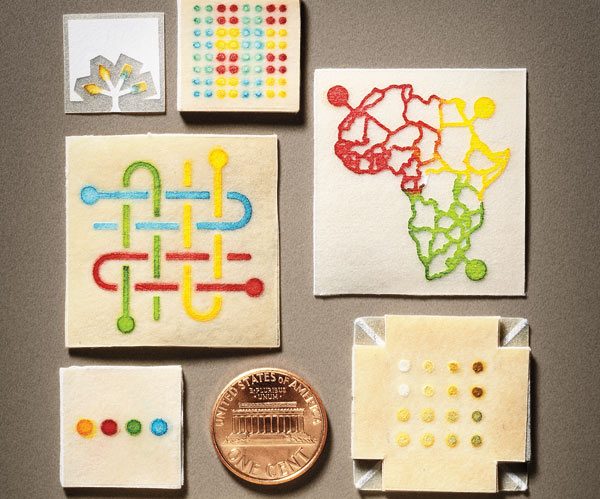

The finished devices are squares of paper roughly the size of postage stamps. The edge of a square is dipped into a urine sample or pressed against a drop of blood, and the liquid moves through channels into testing wells. Depending on the chemicals present, different reactions occur in the wells, turning the paper blue, red, yellow, or green. A reference key is used to interpret the results.

The squares take advantage of paper’s natural ability to rapidly soak up liquids, thus circumventing the need for pumps and other mechanical components common in microfluidic devices. The first step in building the devices is to create tiny channels, about a millimeter in width, that direct the fluid to the test wells. Whitesides and his coworkers soak the paper with a light-sensitive photoresist; ultraviolet light causes polymers in the photoresist to cross-link and harden, creating long, waterproof walls wherever the light hits it. The researchers can even create the desired channels and wells by simply drawing on the paper with a black marker and laying it in sunlight. “What we do is structure the flow of fluid in a sheet, taking advantage of the fact that if the paper is the right kind, fluid wicks and hence pulls itself along the channels,” says Whitesides. Each well is then brushed with a different solution that reacts with specific molecules in blood or urine to trigger a color change.

Paper is easily incinerated, making it easy to safely dispose of used tests. And while paper-based diagnostics (such as pregnancy tests) already exist, Whitesides’s device has an important advantage: a single square can perform many reactions, giving it the potential to diagnose a range of conditions. Meanwhile, its small size means that blood tests require only a tiny sample, allowing a user to simply prick a finger.

Currently, Whitesides is developing a test to diagnose liver failure, which is indicated by elevated levels of certain enzymes in blood. In countries with advanced health care, people who take certain medications undergo regular blood tests to screen for liver problems that the drugs can cause. But people without consistent access to health care do not have that luxury; a paper-based test could give them the same safety margin. Whitesides also wants to develop tests for infectious diseases such as tuberculosis.

To disseminate the technology, Whitesides cofounded the nonprofit Diagnostics for All in Brookline, MA, in 2007. It plans to deploy the liver function tests in an African country around the end of this year. The team hopes that eventually, people with little medical training can administer the tests and photograph the results with a cell phone. Whitesides envisions a center where technicians and doctors can evaluate the images and send back treatment recommendations.

“This is one of the most deployable devices I have seen,” says Albert Folch, an associate professor of bioengineering at the University of Washington, who works with microfluidics. “What is so incredibly clever is that they were able to create photoresist structures embedded inside paper. At the same time, the porosity of the paper acts as the cheapest pump on the planet.”

Recently, the Harvard researchers have made the paper chips into a three-dimensional diagnostic device by layering them with punctured pieces of waterproof tape. A drop of liquid can move across channels and into wells on the first sheet, diffuse down through the holes in the tape, and react in test wells on the second paper layer. The ability to perform many more tests and even carry out two-step reactions with a single sample will enable the device to detect diseases (like malaria or HIV) that require more complicated assays, such as those that use antibodies. Results appear after five minutes to half an hour, depending on the test.

The researchers hope the advanced version of the test can eventually be mass produced using the same printing technology that churns out newspapers. Cost for the materials should be three to five cents. At that price, says Folch, the tests “will have a big impact on health care in areas where transportation and energy access is difficult.”

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.