The Five Most Amazing Things That Were 3-D-Printed This Year

Additive manufacturing has been hyped for years. But in 2017 much of its promise materialized: 3-D printing took a series of big steps out of the realm of niche prototyping and into the world of mass manufacturing. Here’s a look at some of the most impressive things 3-D printers made this year, as well as what their creations portend for the future.

Running shoes

Through a partnership with additive-manufacturing company Carbon (one of our 50 Smartest Companies of 2017), Adidas has imbued its “speed factories” with the ability to print shoes 90 times faster than before. Carbon’s fast printing technology is being used to manufacture elastomer midsoles for the company’s custom athletic shoes. When the doors of the second speed factory open in Atlanta in 2018, Adidas will be poised to manufacture one million shoes a year using the technique.

Eyeglasses, a bevel gear, and a miniature replica of the MIT dome

Actually, these small plastic tchotchkes are not particularly impressive—but the speed at which they were created is. MIT researchers made them on a new machine that prints items so fast you’d swear a video of it in action has been sped up. Items that would once have taken hours to make are now down to minutes. The team published the details of its machine, which uses a heat-generating laser and a high–pressure screw mechanism, in the journal Additive Manufacturing in November.

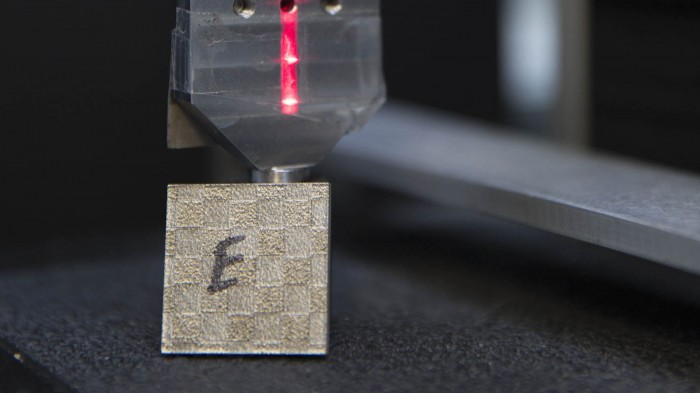

Jet-engine combustion liner

In November GE unveiled its newest metal 3-D printer, as well as a part, called a jet engine combustion liner, printed on the beta version of the machine. Like most metal printers, it uses lasers to transform powder into a solid metal form, but this printer was made with the goal of overcoming size limitations that have dogged previous designs. The combustion liner showed off the size capabilities of the machine: it can print metal parts up to one meter in diameter. When it debuts in 2018, the printer figures to be a centerpiece of the company’s push for 3-D printing to fuel the future of its business. In December, GE also used 3-D-printed metal parts to help set an efficiency record for a natural-gas turbine.

Stronger steel

There’s long been a problem with 3-D-printed steel: you have to trade off strength for ductility. This year, though, a team from Lawrence Livermore National Laboratory has developed an approach that uses a regular laser-sintering printer to control the microscopic grain structure of the metal. This makes it possible to create components with similar ductility to regular stainless steel but twice the strength, and three times that of some previous 3-D-printed types.

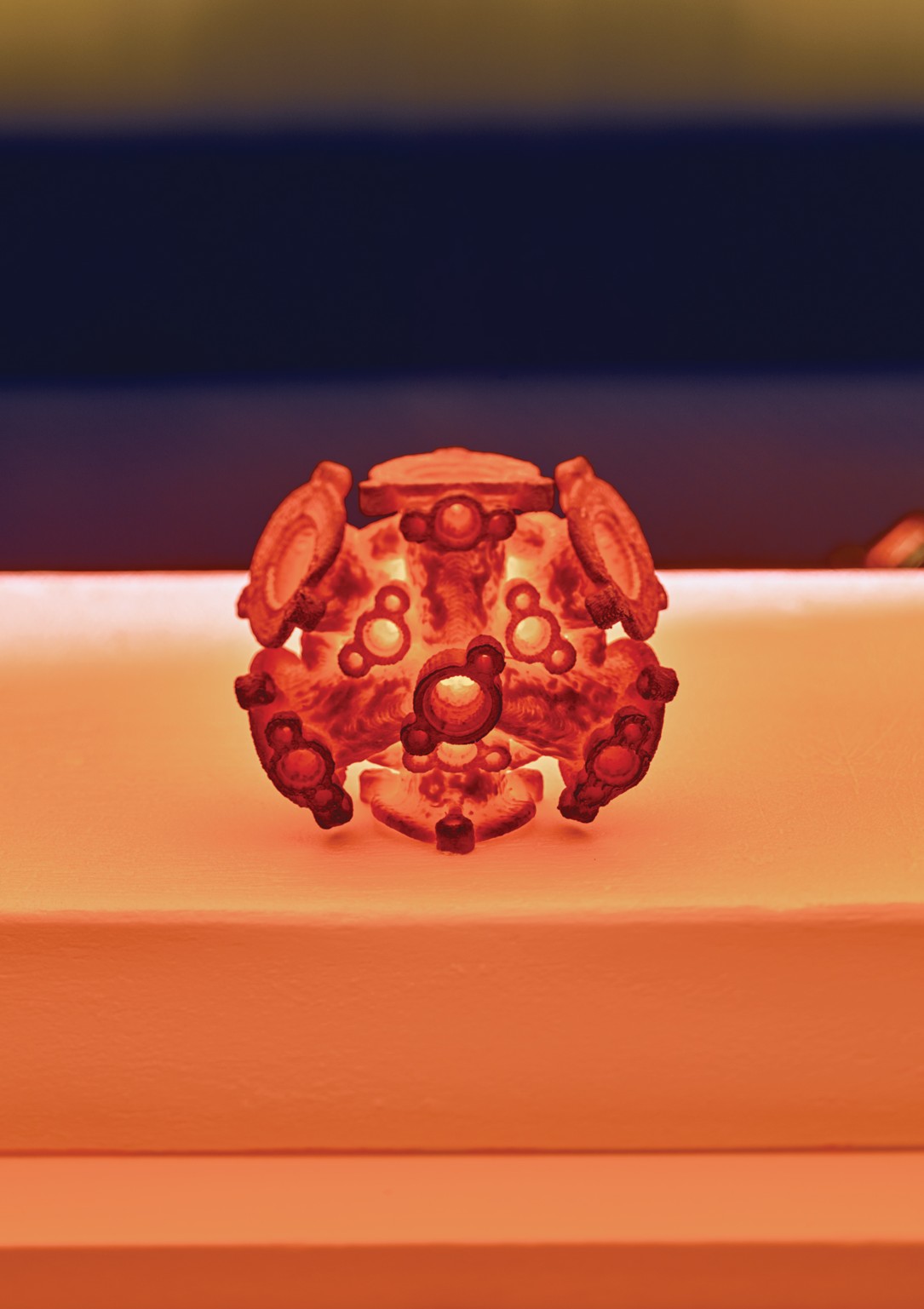

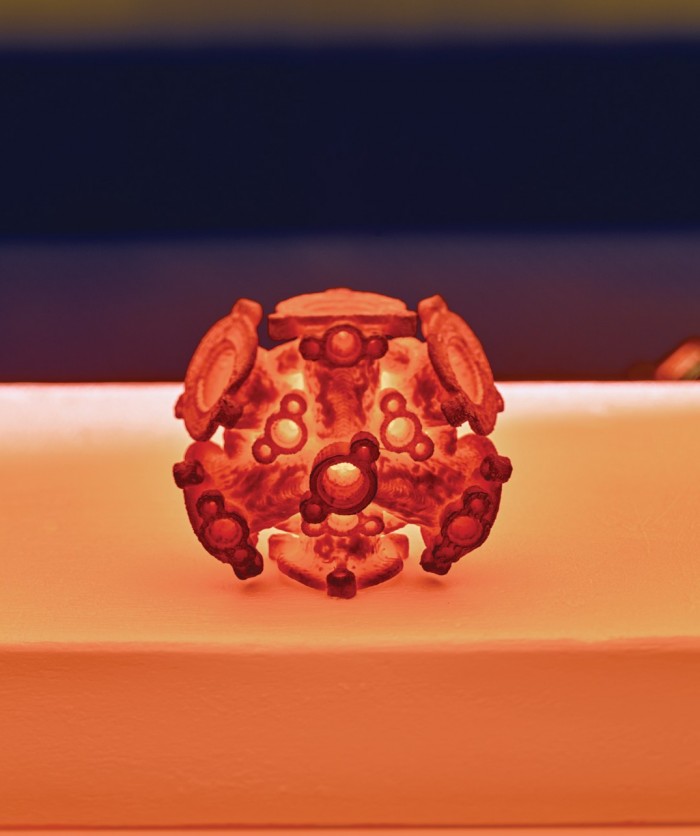

Quickly made metal parts

In April, we reported on Desktop Metal’s revolutionary machines that figure to increase the rate at which metal parts can be printed by a factor of 100. The hydraulic manifold pictured above, which cannot be made through traditional methods, is being processed inside a microwave furnace, which uses temperatures up to 1,400 °C to finish off parts after printing. Printers meant for churning out parts in large-scale production runs are expected to ship in 2018.

Want to explore more about the future of 3-D printing? Check out our recent interactive conversation with entrepreneur Greg Mark.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.