Shellfish Secrets Could Help Save Soldiers

The shells of marine organisms take a beating as they get propelled onto rocky shores by storms and tides or chomped by sharp-toothed predators. But recent research has shown that one type of shell stands above all others in its toughness: the conch. Now, an MIT team has explored the secrets behind these shells’ extraordinary impact resilience—and they’ve shown that this strength could be reproduced in engineered materials, leading to superior protective headgear and body armor.

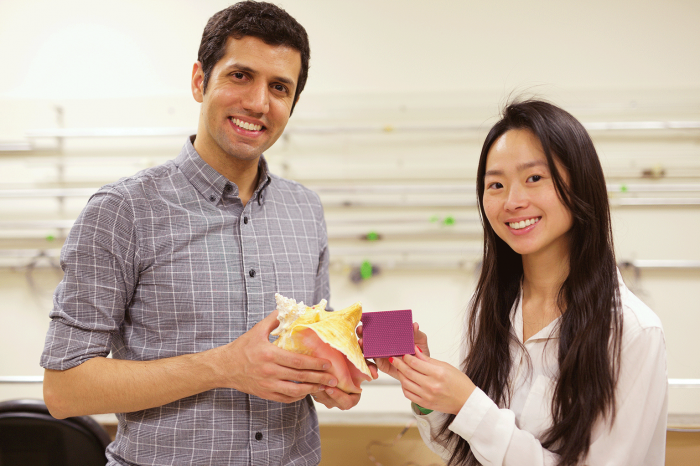

Conch shells “have this really unique architecture,” explains graduate student Grace Gu, who coauthored a paper on the findings with postdoc Mahdi Takaffoli and engineering professor Markus Buehler. This internal structure makes the material 10 times as resistant to fractures as nacre, or mother-of-pearl—the shell’s basic material. The key is that it forms a “zigzag matrix,” Gu says. As a result, a crack “has to go through a kind of a maze” in order to spread.

Until recently, even after the structure of the conch shell was understood, “you couldn’t replicate it that well,” says Buehler, who is the head of the Department of Civil and Environmental Engineering. “But now, our lab has developed 3-D-printing technology that allows us to duplicate that structure and be able to test it.”

Protective helmets and other impact-resistant gear require a combination of strength and toughness, Buehler explains. Strength refers to a material’s ability to resist damage, which steel does well, for example. Toughness, on the other hand, refers to a material’s ability to dissipate energy, as rubber does. Traditional helmets use a metal shell for strength and a flexible liner for both comfort and energy dissipation. But in the new composite material, this combination of qualities is distributed through the whole material.

The printing technology would make it possible to form the conch-inspired material into individualized helmets or body armor. Each helmet, for example, could be “tailored and personalized,” Gu says. “The computer would optimize it for you, based on a scan of your skull, and the helmet would be printed just for you.”

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.