Flexible Glass Could Bring Back the Flip Phone

Imagine a flip phone that fits in your pocket but opens up to reveal a tablet-sized screen. Glassmakers are already manufacturing bendable glass that’s thinner than a human hair, and they say foldable glass is just around the corner.

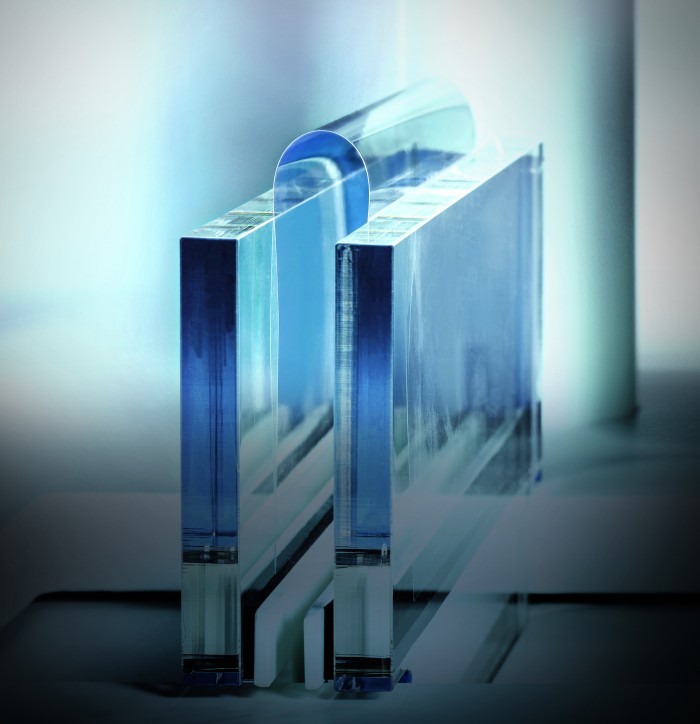

German glassmaker Schott is now mass-manufacturing glass that’s ultrathin, strong, and smooth. Electronics can be made on it, and it flexes like plastic. The first consumer product to use Schott’s new glass is the fingerprint sensor on a smartphone made by LeTV, a large video-streaming company in China. Company representatives hope that this and other niche applications will give the new material a foothold while industrial designers play around with it.

Rüdiger Sprengard, director of business development for ultrathin glass at Schott in Mainz, Germany, says the company can now continuously manufacture flexible glass in kilometers-long sheets. Sprengard recently brought some demos to show off in a San Francisco hotel room. He showed me a spool of glass half a meter wide and half a kilometer long, which looks like a fat roll of cellophane. A machine continuously bends a smaller piece of the glass down to a radius of nine millimeters. It doesn’t fold yet, but Sprengard says they’re working on it and hope to have it in a few years.

After giving me gloves and goggles, Sprengard hands me a sheet that’s about the size of a sheet of office paper, but thinner and stiffer. Paper is about 100 micrometers thick; this sheet is 70 micrometers. As I’m flopping it around in my hands, treating it like a piece of plastic, one of the company representatives steps back. It’s still glass, after all, and she’s not wearing any eye protection. When they first started experimenting with making glass this thin, it used to break much more easily, Sprengard explains. “About two years ago you wouldn’t have been able to handle it like that,” he says.

That fragility is why mass production of flexible glass has been so challenging. To make it work, Schott had to develop new methods that built on those already used to make ultrastrong glass like Corning’s Gorilla Glass, which is found on the surface of many smartphones. Gorilla Glass and other products made by both companies are toughened through a process called ion exchange.

To make glass thinner and thinner—and therefore more flexible—glassmakers have to figure out how to strengthen it. Schott is the first company to make ultrathin glass that can be chemically strengthened by ion exchange, which was a challenge, says Eric Urruti, vice president of R&D at Schott North America in Pennsylvania. The glass is drawn down out of a huge, molten tank into sheets and run through rollers. It is then run through a bath of molten potassium. Smaller sodium ions leave the glass and are replaced by larger potassium ions, creating compression within the glass itself.

The more the glass is squeezed, the stronger it becomes. Controlling this compressive process in ever-thinner glass is difficult—there’s simply less material to work with. The company currently makes glass as thin as 20 micrometers. Maintaining continuous thickness across kilometers is also a challenge. And any tiny flaws must be smoothed over—or that’s where your phone screen will shatter.

As the glass gets thinner, the challenges change, says Scott Forester, director of Gorilla Glass Innovations at Corning, headquartered in New York. Corning is also developing ultrathin glass, and sells a product that’s 100 micrometers thick. As cover glass (the kind found on the surface of phones) gets thinner, it’s more vulnerable to being punctured. But compared to plastic, glass’s puncture resistance will always be superior, he says.

Flexible electronics are already making some headway, but not in a way that’s obvious to consumers. Today, flexible screens are used in devices like the Galaxy Edge, a phone with a rigid screen that curves at the sides. The OLED display within the phone is made on plastic and laminated to a Corning Gorilla glass coverslip. If that cover glass were flexible—and with other changes—the device itself could be flexible. Cover glass today is 10 times thicker—usually about 550 micrometers (half a millimeter)—than the glass Schott is showing off.

Forester says the pieces are in place for more flexible consumer electronics. The glass is ready and the flexible circuits are almost ready. Now they’re waiting on the designers—and on consumers. “There has to be a form factor that adds value for people,” he says.

Right now it’s not clear what that will be. But Corning is also working on glass that will enable it. Since ion exchange becomes more difficult in thinner materials, the company is looking at changing the underlying matrix of the glass itself—a more fundamental change in the material. Humans have been using glass since the Stone Age, but there’s still a lot more chemistry to explore, says Forester. “Our scientists test 30 or 40 new glasses each day,” he says.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.