How to 3-D-Print a Hydraulic-Powered Robot

Fluid is an important, if underappreciated, component in modern robotics. Its chief role is to generate, control, and transmit power throughout complex devices—an engineering science known as hydraulics.

One problem with hydraulic components is that the pressurized piping required to make it all work is often treated as a system that is more or less independent from the rest of the device.

That has important consequences for the way robots are designed and built. Hydraulics dramatically increases the complexity and the time required to build, operate, and maintain robots.

Today, that looks set to change thanks to the work of Robert MacCurdy and pals at MIT. These guys have modified a 3-D printer to make it capable of incorporating hydraulics into any design.

That makes it possible to design and build hydraulic machines in a single step for the first time. “Until now there has been no means of incorporating robust, high-performance force-transmission elements directly into a 3-D-printed part,” they say.

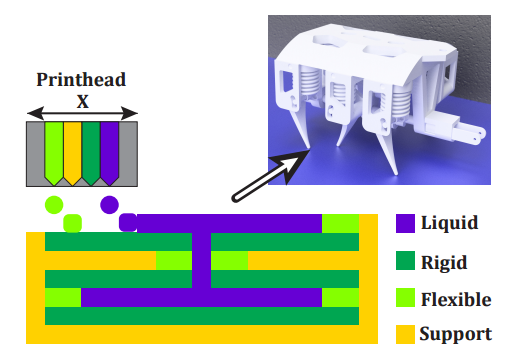

The approach is straightforward. The most advanced 3-D printers are able to print several materials at the same time. That’s useful since it allows them to incorporate materials with different properties such as flexibility, color, and so on.

These 3-D printers work by building up 3-D shapes one layer at a time. They first put a drop of liquid ink in place and immediately zap it with ultraviolet light, to cure, or solidify, it. They place a drop next to this and cure it and so on to create the first layer. The next layer goes on top of this.

MacCurdy and co’s idea is to treat the hydraulic liquid like any other printer material. They do this by swapping a reservoir of curable printer ink with a reservoir of liquid that cannot be cured by UV light and so remains liquid. When it comes to design, they treat the liquid in exactly the same way as the other materials.

The advantages are manifold. This approach immediately allows the creation of objects that contain complex fluid-filled circuits. Since these circuits are closed, applying pressure at one end of a circuit transmits the force along it.

And the flexibility of modern printing materials means that it is also possible to convert this change in pressure to mechanical movement and vice versa.

MacCurdy and co put the technique through its paces by printing a number of hydraulic devices. For example, they print a gear pump—essentially a pair of enmeshed cogs in a tube that, as they turn, move fluid that is trapped between the teeth. This pumps the fluid in one direction but prevents it flowing back because the teeth fit closely together.

They also printed a bellows actuator to transmit force through a liquid. Finally, they printed a set of fluid-actuated grippers made of soft, silicone rubber that is capable of picking up delicate objects such as eggs.

Usefully, MacCurdy and co lay out what they’ve learned to provide a kind of do-it-yourself guide for anybody thinking of trying the same tricks (although they will need the same kind of high-end printer—a Stratasys Objet260 Connex, in this case).

That’s impressive work that significantly extends the capability of 3-D printing techniques. “This approach allows complex, functional, multi-part robotic assemblies that use hydraulic force transmission to be automatically fabricated,” say McCurdy and co.

We’ll look forward to seeing what they come up with.

Ref: http://arxiv.org/abs/1512.03744: Printable Hydraulics: A Method for Fabricating Robots by 3-D Co-Printing Solids and Liquids

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.