A Robotic Tabletop Makes Simple Structures All by Itself

A robotic table that’s capable of manipulating objects placed on its surface may inspire new types of telepresence interfaces, as well as new approaches to manufacturing.

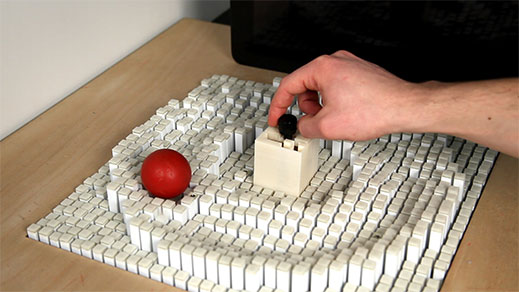

The device was developed by Sean Follmer and colleagues at the MIT Media Lab. Its surface is made up of the tops of an array of square pins, each roughly a centimeter wide. These pins are powered by a small motor and move up and down, under the control of a computer, pushing objects around on the table.

A recent experiment, conducted by Philipp Schoessler, a student at the Media Lab, shows how the table can manipulate several specially designed blocks. Activating the pins at the correct speed can cause the blocks to flip over, or even to hop on top of one another, building a simple structure. To build more complex structures, the researchers used a 3-D printer to make blocks with magnetized connectors on each side, allowing them to lock together.

The researchers also developed “kinematic blocks” with buttons or knobs on top that could be used to manipulate the pins beneath—a user could then control the movements of another block by pressing the button or turning the knob on a control block. The work was presented early this month at the ACM Symposium on User Interface Software and Technology.

Follmer, now an assistant professor at Stanford University, says the approach could prove useful as part of an industrial production line.

“We’re thinking about a much more advanced assembly line where you could move things,” Follmer says. “What would be interesting would be a kind of conveyor belt where you can manipulate things directly but also in conjunction with other robotic arms.”

Some companies are, in fact, already showing an interest in such technology for manufacturing. Festo, a German company that makes manufacturing equipment, has demonstrated a system capable of maneuvering different objects in multiple directions at once. The technology, which the company calls Wave Handling, consists of a conveyor with an array of electronically controlled bellows beneath. As these bellows are inflated, the portion of the conveyor above pushes upward. The approach can be used to move objects in different directions around the conveyor.

Follmer says more complex physical interfaces of this kind will be enabled by cheaper robotic hardware. “We’re seeing this real shift in robots becoming cheaper and faster, and having many, many more of them in the consumer and industrial market,” he says. “That’s going to decrease the cost of many of these things.”

Follmer and colleagues previously showed how their table could be combined with a video screen to enable a form of telepresence that lets a user manipulate objects remotely.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.