Spinning Synthetic Spider Silk

Materials scientists have spent decades trying to mimic spider silk. Not only are some of these silks stronger than steel, but they have combinations of properties not found in synthetic fibers like the Kevlar used for bulletproof vests or the petroleum-based polyester found in clothes.

Bottom: David Breslauer

But while several companies have produced artificial silk for small-scale applications, it can’t be widely used to create new kinds of tough, durable, lightweight, petroleum-free materials unless it can be made in very large volumes. A startup called Bolt Threads, in Emeryville, California, might have found a way.

Two of its founders are Dan Widmaier and David Breslauer, who have been working on the problem since they were grad students at the University of California, San Francisco, and UC Berkeley in 2007. They use synthetic-biology techniques to engineer proteins that can be spun into fibers with properties they can alter depending on their customers’ needs.

That versatility is crucial. While synthetic fibers made from petroleum tend to be good at one thing, silk can be reëngineered to suit diverse applications. Spiders themselves do this, fine-tuning their silk to make strong structural struts for their webs, sticky spots to capture prey, and a tough line to hang from.

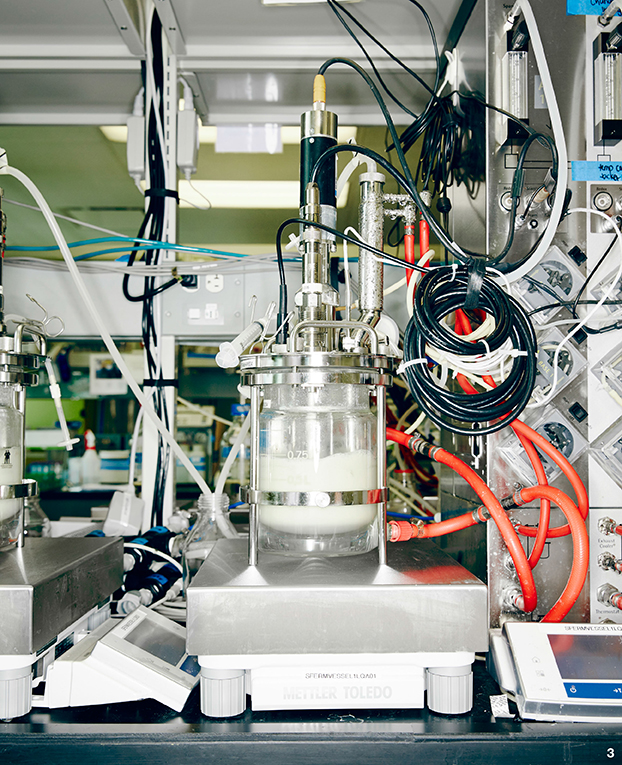

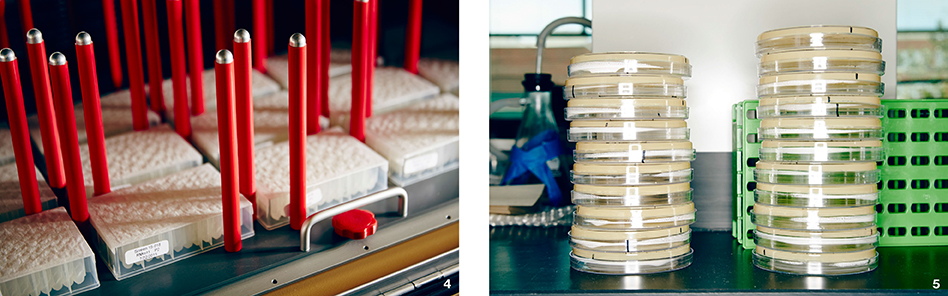

At Bolt Threads, genetically engineered yeast brew silk proteins that can be spun into fibers. The properties of those fibers can be altered by tinkering with the protein concentration and the temperature, tension, and other aspects of the spinning process.

6. Purified spider-silk proteins are ready to be made into fibers.

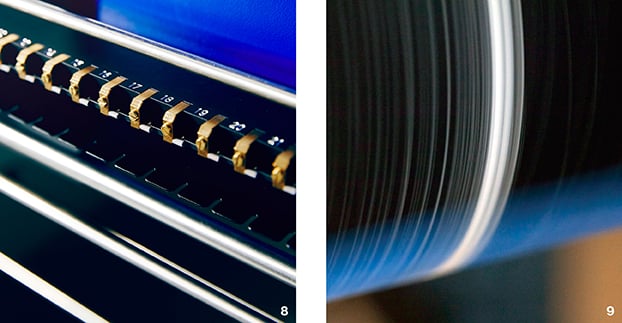

9. After being spun and treated, the silk fibers are spooled.

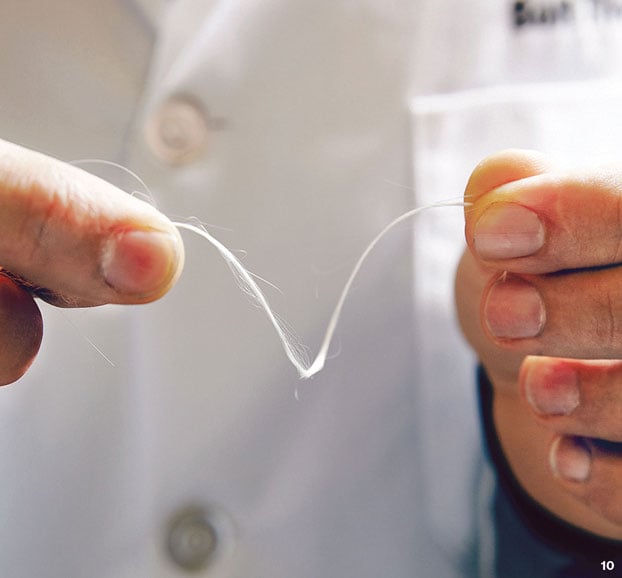

The company says its first products will be in consumer apparel in 2016. Its fibers, which are much finer than natural materials like cotton and stronger than nylon, could lend clothes the best qualities of both natural and artificial fibers: they would be soft and light, while durable enough to toss in the wash repeatedly. However, the company won’t specify which properties it aims to achieve in its early products.

Widmaier and Breslauer do say, however, that clothes are only the beginning—an application that proves the company can manufacture at large volumes. “If we can get it to that scale,” Widmaier says, “we can do anything.”

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.