High-Speed 3-D Printing

A new additive manufacturing technology is 25 to 100 times faster than conventional 3-D printing, and produces stronger parts at a lower cost.

The technology was developed by a startup called Carbon3D, which was founded in 2013. The process is described today in a paper published in the journal Science.

3-D printing produces objects by depositing or solidifying one layer of material at a time, a process that lends itself to making very complex objects, but it’s much slower and more expensive than large-volume manufacturing techniques.

Carbon3D’s technology is fast enough that it could compete with conventional mass manufacturing in many cases, says Joseph DeSimone, cofounder and CEO of Carbon3D.

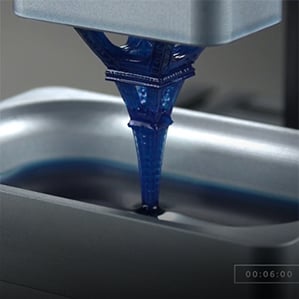

The new technology has some features in common with 3-D printing, but it makes objects continuously rather than in discrete layers, making it much faster. In a video of the process, it looks as if an object gradually emerges from a thin layer of liquid.

The new process is related to stereolithography, in which lasers trace a pattern on a liquid that is engineered to solidify when exposed to light. Normally, to form each layer, the laser has to be turned off so that more liquid can be spread out. This slows the process, and the “interfaces” between layers create weak points in a finished object.

The founders of Carbon 3D, who are researchers at North Carolina State University and the University of North Carolina, developed a way to make the process continuous and ensure that there are no interfaces between layers. The key is to modify the liquid so that it doesn’t immediately solidify when exposed to light. They achieved this by introducing a thin layer of oxygen that temporarily blocks the reactions that produce a solid.

The process works with a variety of commercial plastics, and the researchers are working on using different liquids during the process, to make parts from blended materials. Carbon3D has raised over $41 million in venture funding to date from firms such as Sequoia Capital.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.