Stacking Cells Could Make Solar as Cheap as Natural Gas

When experts talk about future solar cells, they usually bring up exotic materials and physical phenomena. In the short term, however, a much simpler approach—stacking different semiconducting materials that collect different frequencies of light—could provide nearly as much of an increase in efficiency as any radical new design. And a new manufacturing technique could soon make this approach practical.

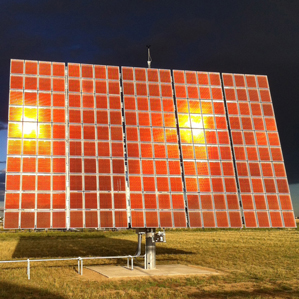

The startup Semprius, based in Durham, North Carolina, says it can produce very efficient stacked solar cells quickly and cheaply, opening the door to efficiencies as high as 50 percent. (Conventional solar cells convert less than 25 percent of the energy in sunlight into electricity.)

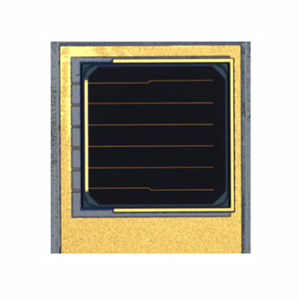

Semprius has come up with three key innovations: a cheap, fast way to stack cells, a proprietary way to electrically connect cells, and a new kind of glue for holding the cells together. In its designs, Semprius uses tiny individual solar cells, each less than a millimeter across. That reduces costs for cooling and also helps improve efficiency.

The conventional way to stack semiconductors is to grow layers on top of each other. But not all semiconductors can be combined this way, because their crystalline structure doesn’t allow it (see “Adaptive Material Could Cut the Cost of Solar in Half”). Semprius grows semiconductor materials in the conventional way but also stacks several different combinations, resulting in a solar panel that can capture more energy from sunlight.

Semprius has demonstrated cells made of three semiconductor materials stacked on top of a fourth solar cell that would not have been compatible otherwise. It has made two versions of the device this year, one with an efficiency of 43.9 percent and the other, using slightly different materials, with an efficiency of 44.1 percent.

In addition to being fast and precise, the approach also makes it possible to reuse the expensive crystalline wafers that multijunction solar cells are grown on. Eventually the company hopes to stack two multijunction devices, for a total of five or six semiconductors with a “very high performance, beyond 50 percent efficiency,” says Scott Burroughs, vice president of technology at Semprius. He says the company hopes to achieve this in three to five years.

The one catch is that the cells will be more costly than conventional ones. Sarah Kurtz, a principal scientist at the National Renewable Energy Laboratory, says costs won’t come down until production happens at a large scale.

With economies of scale, however, such cells could improve the economics of solar power. At a scale of 80 to 100 megawatts a year of manufacturing capacity, a cell with 50 percent efficiency would make it possible to reach costs of less than five cents per kilowatt-hour, Burroughs says. The U.S. Energy Information Administration estimates that new natural-gas power plants will produce electricity at 6.4 cents per kilowatt-hour.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.