Flexible Solar Cells Can Stick to Just About Any Surface

Solar panels are typically heavy, which makes them expensive to install, and rigid, which limits where they can be used. In the current issue of Nature Scientific Reports, researchers describe a novel, potentially cheap way to make solar cells that are both lightweight and flexible.

The technique is meant to work with thin-film solar cells. The active part of thin-film cells—the part that gathers sunlight and generates electricity—is thin enough to be flexible, but the cells usually have to be manufactured on rigid materials such as glass to achieve the highest quality.

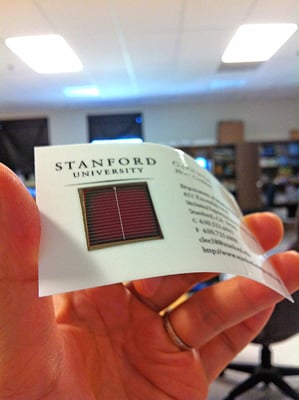

Researchers led by Xiaolin Zheng, a professor of mechanical engineering at Stanford University, demonstrated a way to transfer the active materials of the solar cell from a rigid substrate onto another surface, such as a sheet of paper or plastic, the roof of a car, or the back of a smartphone. As with other solar cells, wires would then be connected to deliver power, but flexible solar cells could be used on curved surfaces, and, because they’re lightweight, they would be easier to install than conventional panels.

Although Zheng has demonstrated that the process can transfer solar cells even to cheap surfaces such as paper, in practical applications, the materials used would be limited by the need to protect the cells from the elements.

These aren’t the first flexible solar panels. Several companies already manufacture them (see “A Solar Startup that Isn’t Afraid of Solyndra’s Ghost” and “Solar Shingles See the Light of Day”). But Zheng says prior approaches to making flexible solar cells have drawbacks. Manufacturers often modify processing steps to accommodate flexible substrate materials that can’t tolerate high temperatures or certain chemicals, but this can reduce the performance of the resulting solar cell. And manufacturers have typically used costly flexible substrate materials, such as foils with extremely uniform surfaces, in order to produce high-quality thin films.

The trick to peeling thin-film silicon away from a solid substrate of silicon dioxide involves depositing a layer of nickel on top of an underlying wafer. After the cell is finished, it’s immersed in room-temperature water. The water interacts with the nickel and silicon dioxide, causing the solar cell to come loose. It can then be peeled away and deposited onto another material. The researchers demonstrated that the efficiency of the solar cell wasn’t affected by the transfer process.

The current paper shows that the process works for dislodging a solar cell from a silicon and silicon dioxide wafer. Zheng says the group has also demonstrated the process with solar cells made on a glass surface, but this work has not yet been published. This could make it possible to use the technique with copper indium gallium selenide solar cells, which are nearly twice as efficient as amorphous ones.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.