Paper-thin loudspeakers

Big sound from a thin film.

MIT engineers have developed a paper-thin, low-power loudspeaker that can turn any surface into an active audio source.

This thin-film loudspeaker produces sound with minimal distortion while using a fraction of the energy required by a traditional loudspeaker. A hand-size version weighs about as much as a dime and can generate high-quality sound no matter what surface the film is bonded to.

The researchers’ deceptively simple fabrication technique requires only three basic steps and can be scaled up to produce ultrathin loudspeakers large enough to cover the inside of an automobile or to wallpaper a room.

Such speakers could provide active noise cancellation in clamorous environments, such as an airplane cockpit, by generating sound of the same amplitude but opposite phase; the two sounds cancel each other out. The flexible device could also be used for immersive entertainment, perhaps by providing three-dimensional audio in a theater or theme park ride. It is well suited for applications in smart devices where battery life is limited.

“It feels remarkable to take what looks like a slender sheet of paper, attach two clips to it, plug it into the headphone port of your computer, and start hearing sounds emanating from it. It can be used anywhere. One just needs a smidgen of electrical power to run it,” says professor Vladimir Bulović, director of MIT.nano and senior author of the paper along with electrical engineering professor Jeffrey Lang. Postdoc Jinchi Han is lead author.

A typical loudspeaker uses electric current inputs that pass through a coil of wire, which generates a magnetic field. This moves a speaker membrane, which moves the air above it to make the sound we hear. By contrast, the new loudspeaker uses a thin film of a shaped piezoelectric material that expands and contracts when voltage is applied over it, which moves the air above it and generates sound.

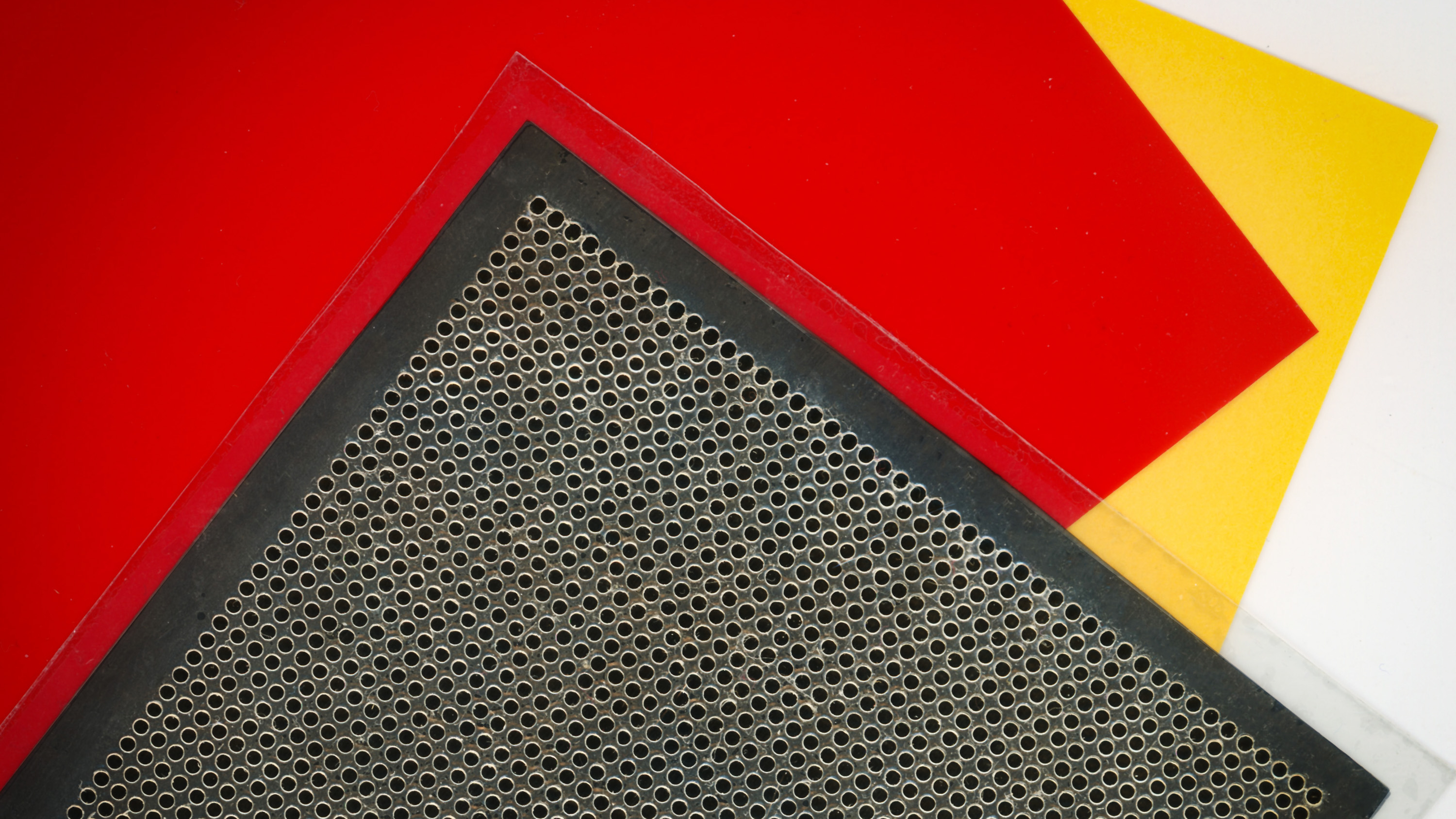

Most thin-film loudspeakers are freestanding because the film must bend freely to produce sound, and mounting them onto a surface would impede the vibration. So rather than having the entire material vibrate, the new design relies on tiny domes on a thin layer of piezoelectric material, each of which vibrates. These domes, each only a few hair-widths across, are surrounded by spacer layers on the top and bottom of the film that protect them from the mounting surface while still enabling them to vibrate freely. The same spacer layers protect the domes from abrasion and impact during day-to-day handling, enhancing the loudspeaker’s durability.

Because the tiny domes are vibrating, rather than the entire film, the loudspeaker has a high-enough resonance frequency to be used effectively for ultrasound applications like imaging, Han says. Ultrasound imaging uses very-high-frequency sound waves to produce images, and higher frequencies yield better image resolution.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.