One man’s crusade to end a global scourge with better salt

Iodized salt is one of history's great public health triumphs, virtually eliminating goiter. Venkatesh Mannar wants to do the same to anemia by adding iron.

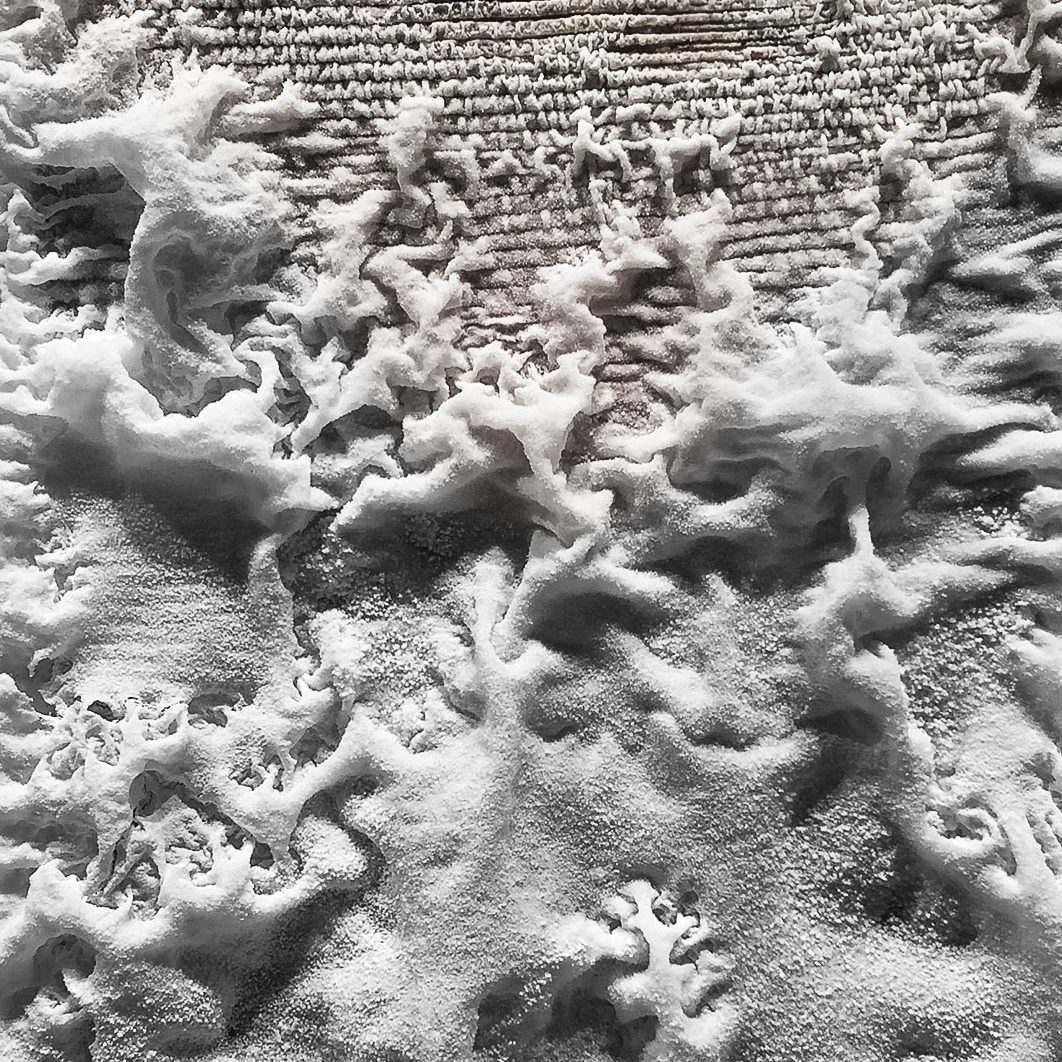

When he was growing up, Venkatesh Mannar and his siblings treated the family saltworks as their playground: they would slide down mountains of salt drying in the sun the way other children might sled down snow-covered hillsides.

The salt operation, in the southern Indian port city of Thoothukudi, had been founded by his grandfather’s grandfather. As they had for generations, men stood in the brine, using wooden trowels to rake thick crusts of salt that formed on shallow pools of seawater, and then piled it high to dry into crystals.

After several years in the United States, first studying and then working at salt producers that used giant mechanized harvesters, Mannar returned to India in 1972, intent on building a large, modern saltworks facility near Chennai with the mechanical know-how he’d gained. Then, in the early 1980s, the world began to take an interest in eliminating iodine deficiency, which causes problems ranging from hypothyroidism to learning difficulties. Mannar, while continuing to run his business, became a consultant for UNICEF and the World Health Organization (WHO). He visited countries in Asia, Africa, and Latin America to persuade them to iodize their salt, a practice that has been common in much of the developed world for decades.

He recalls arriving once in the Democratic Republic of the Congo and discovering that the WHO representatives there couldn’t even tell him where salt was being produced: “They had no information!” Mannar took a car to a local market and strolled around, polling the shopkeepers selling salt on where they got it. After reconstructing the supply chain that way, he tracked down the country’s salt producers to talk to them about iodine. Mannar figures he went to over 50 countries on similar missions. Today, an estimated 6 billion people globally have access to iodized salt, in no small part thanks to Mannar.

But from the early days, Mannar was also concerned with another element that many people don’t get enough of: iron. A lack of it is one cause of anemia, which affects over 1.6 billion people. The condition is especially prevalent in South Asia and sub-Saharan Africa. In India alone, more than half of reproductive-age women are anemic, along with nearly 60% of children under five. Its symptoms include dizziness, poor maternal and infant health, decreased cognitive function, and the telltale listlessness that Indians call “lack of blood.”

Mannar thought salt, which is consumed nearly universally and with almost every meal, might be the best vehicle to deliver small amounts of iron that would have a huge public health impact. “Even from the 1970s I was very conscious about iron deficiency,” he says. “It became a secondary priority because of the push with iodine.”

Mannar eventually made defeating anemia with iron-enriched salt part of his life’s mission. Adding iron to salt that is already iodized—resulting in so-called double-fortified salt—has turned out to be a technical challenge orders of magnitude harder than iodization. Getting manufacturers and the public to adopt it is another problem again. But if the effort succeeds, Mannar and his backers hope to add yet more essential minerals, turning humble table salt into one of the most potent public health tools the world has at its disposal.

If you ever sat at the breakfast table as a child and wondered how your morning bowl of cereal could boast that it provided so much of the recommended daily allowances of science-class-sounding things like thiamine, niacin, and riboflavin, then you have experienced the wonders of micronutrient fortification, or supplementing commonly eaten foods with trace minerals and vitamins.

Micronutrient fortification can be designed for specific populations (as with fortified breakfast cereals, cacao-based drinks for kids, or fortified infant formula), or for everyone. Iodized salt, milk fortified with vitamins A and D, and enriched flour are a few examples.

The idea that a lack of certain trace elements causes common afflictions was established by nutritionists starting in the 19th century. A shortage of iodine was tied to goiter—an inflammation of the thyroid gland, which needs iodine to synthesize key hormones—and to “cretinism,” an archaic name for developmental delays and cognitive impairments. A lack of zinc leads to diarrheal disease in children. Other ailments caused by nutrient deficiencies were also identified, and specific foods were prescribed as cures: lemons for scurvy, cod liver oil for rickets, meat and milk for beriberi. (In one of the earliest documented instances of fortification, in 1873, French bakers included cod liver oil in bread destined for hospitalized children.)

In 1906, Frederick Gowland Hopkins of Cambridge University challenged his colleagues to learn more about what he called “unsuspected dietetic factors” in an organism’s health. His first paper on “accessory factors” was published in 1912; it would take several decades for scientists to come to an understanding of the chemical structures of what we now call vitamins.

Meanwhile, during the First World War, US Army officials noticed a pattern among young men called up for the draft. Goiter, identifiable by the prominent swelling of the thyroid in the front of the neck, was more common among men from the center of the country, and less so among draftees from the coasts.

Meanwhile, during the First World War, US Army officials noticed a pattern among young men called up for the draft. Goiter, identifiable by the prominent swelling of the thyroid in the front of the neck, was more common among men from the center of the country, and less so among draftees from the coasts. One medical history of salt iodization records that “according to US Selective Service regulations, more men were disqualified for military service in Northern Michigan for large and toxic goiters than for any other medical disorder”; surveillance studies ultimately found a prevalence above 64% in some parts of the state.

Why did their coastal peers fare better? Seawater contains iodine, some of which evaporates into the air and then returns to earth in rain. Coastal soil, therefore, is far richer in iodine than soil inland, and plants grown near the coasts have higher iodine levels. Seaweed and seafood, which are more common in coastal diets, also contain enough iodine to make a nutritional difference.

Authorities in three French provinces had begun distributing iodine tablets as early as the 1860s. In 1922, landlocked Switzerland became the first country to systematically iodize salt. By 1924, the Morton salt company, based in Chicago, began selling iodized salt across the United States, and eventually 90% of American households came to use it.

Not until 1990 did the UN World Summit for Children set the goal of eliminating iodine deficiency disorders worldwide, but the effort has been a resounding success: the number of countries classified as iodine deficient fell from 110 in 1990 to 25 by 2015. Meanwhile, fortifying milk with vitamin D has led to the near eradication of rickets, and enriching flour with niacin and other minerals eliminated pellagra, a condition marked by diarrhea, dermatitis, and dementia that killed as many as 7,000 Americans annually at its peak in the late 1920s but was virtually nonexistent by 1950.

The striking exception to this litany of successes is anemia. Though the disease has many causes, including parasitic infections and other nutrient deficiencies, the most common is a lack of iron, which is responsible for about half of worldwide anemia cases. Anemia results in weakness and reduced cognition. For pregnant women it can, along with folic acid deficiency, increase the odds of birth defects like anencephaly, which is usually fatal.

Economists believe high rates of iron-deficiency anemia also have a macroeconomic effect, reducing individual productivity by as much as 40% and reducing GDP by over 1%. According to the Copenhagen Consensus Center, which does cost-benefit analyses of large-scale social interventions, salt iodization costs around five cents per person per year, and one dollar spent on it generates as much as $30 in saved health-care costs and higher economic productivity. Iron fortification, it’s estimated, would generate almost $9 for each dollar spent—not as dramatic as iodization, but still a substantial impact.

Part of the reason anemia is so prevalent in India is that almost 200 million Indians live in extreme poverty, and many rarely or never eat meat, either for religious reasons or because it is simply unaffordable. Grains and pulses, the staples of most Indian diets, are rich in phytates, compounds that inhibit the absorption of iron, exacerbating the problem. Anemia was common even in Mannar’s relatively well-off social circle. Though more severe in India than elsewhere, it isn’t a problem confined to the poor world. Some 3.5 million people are diagnosed with anemia each year in the United States, according to the Centers for Disease Control, and over 5,000 die from it annually.

But, as Mannar notes, richer people can visit a doctor and buy iron supplements, while poorer Indians, especially in rural areas, likely can’t. Government interventions in India, such as a program to give pregnant women iron tablets, had also made little sustained impact. Distributing pills to hundreds of millions of people and persuading them to take them regularly was hard. Iodized salt, however, was already in shops and kitchens, and used in every meal. Why not, Mannar thought, just add iron to it as well?

The idea had been around since 1969. But as Mannar and competing groups in India and Switzerland (among others) would discover, both the chemistry of iron and the complexities of nutrition made things considerably harder.

Iodizing salt is a relatively simple matter: a solution containing 2% to 4% potassium iodate is dripped or sprayed on salt that has already been dried and refined. Alternatively, the potassium iodate can be mixed with a filler, sprinkled over dry salt, and mixed again.

Adding iron to iodized salt—making double-fortified salt, or DFS—turns out to be an entirely different class of problem.

When iron comes into contact with potassium iodate, they react. The iodine evaporates, and the iron forms compounds that are less easily absorbed by the body. The salt darkens and takes on a metallic taste—hardly something someone would want to sprinkle on food.

Mannar learned all of this the hard way. In 1993, he walked into the office of Levente Diosady, a professor of food engineering at the University of Toronto who specialized in processing edible oilseeds, and told him about the idea for DFS. “He said, ‘This should be pretty easy—can we do a couple of tests?’” Diosady recalls. “I said, ‘Yeah, we can do a couple of tests, but it probably won’t be that easy.’” The two received a small grant from a recently created group called the Micronutrient Initiative to explore the technical side of creating DFS.

Diosady knew the key was to keep the iron and iodine from coming into contact with one another, but he didn’t have a clear idea of how to do it. He and one of his lab technicians tried to create iodine microcapsules with a thin, water-resistant coating around each particle, to form a barrier between the iodine and the iron. They tried several encapsulant formulas, but they found that to mix evenly with salt, the spray-dried microcapsules had to be ground up very fine. In a test in Ghana, consumers complained that the results were clumpy.

“At that point, we went back and said, Okay, well, what can we do to make it bigger? So we started looking at agglomerating these iodine particles to make them more or less match salt in size,” says Diosady. “That was the goal: to make stuff that matches salt grains in size to prevent separation.”

In the early years of the project, salt in most countries was neither as uniform nor as sparkling white as it is today, which worked to Diosady’s advantage. “Color was not a big deal. Particle size was not a big deal. It was variable,” he recalls. But as production centralized, salt became more consistent in appearance and taste. “We were chasing a moving target—the quality of salt over the last 20 years has improved steadily,” Diosady says.

Unable to get the iodine capsules to work the way they wanted, Diosady and his team decided to change tack and focus on encapsulating the iron instead. That way whatever they came up with could, in principle, be mixed in with existing iodized salt.

That left the question of what kind of iron to use. “We went and tried a whole slew of iron compounds,” says Diosady. Most resulted in an off-color salt that would never fly with consumers. He’s reminded of these failed attempts every year, when winter arrives in Toronto. “I still use salt in my driveway which is yellow, green—all the different colors that these things came up with,” he says.

Mannar suggested ferrous fumarate, a compound widely used in iron tablets because the body absorbs it easily. One of the cheapest forms, it also has the advantage of being flavorless—other iron compounds can taste like a rusty pipe.

Ferrous fumarate comes in powder form. Diosady and his graduate students would suspend the powder in a precisely controlled stream of air that flows up into a cone-shaped container, while simultaneously injecting an adhesive that allows the particles to coagulate in salt-grain-size clumps. These clumps could then be sprayed with a waterproof coating, so that if they encountered any humidity they wouldn’t dissolve, thereby preventing the iron within from reacting with the iodine. These little particles now formed an iron “premix” that could be added to iodized salt.

There was just one problem. Ferrous fumarate ranges in color from a cocoa brown to the bright red of paprika or cayenne. Diosady recalls bringing the iron-enriched salt to a meeting of specialists led by Mannar. “They said, ‘Well, you know, we’ve been spending the last 10 years telling people that salt should be white and clear and clean with nothing in it. And here you are doing this, and it looks like there’s mouse droppings in it.’”

He’s reminded of these failed attempts every year, when winter arrives in Toronto. “I still use salt in my driveway which is yellow, green—all the different colors that these things came up with,” he says.

To get the right color, they eventually settled on a formula based on stearin (a tasteless vegetable fat used in everything from candles to confectionery), which provides the waterproof layer, mixed with enough titanium dioxide (an inert food additive, and the same mineral that makes some sunscreens chalky) to tint the particles white.

But these techniques relied on a sophisticated piece of equipment known as a fluidized-bed agglomerator, used in pharmaceutical manufacturing. The machines can cost a couple of million dollars each. Diosady’s team gradually ramped up to making the premix in 600-kilogram batches, enough for 120,000 kilograms of double-fortified salt, but there was no way developing countries would be able to afford the technology.

The team needed a cheaper, simpler method. They eventually hit upon extrusion—squeezing a “dough” made of ferrous fumarate mixed with semolina, water, and a tiny bit of shortening through a restaurant pasta machine, to create strands the diameter of angel-hair pasta. These are cut into pellets of equal length and diameter, which are then sieved to ensure evenly sized pieces of no more than 800 micrometers, or a 30th of an inch: around the size of a single grain of salt. The pellets are, as before, coated in titanium dioxide and stearin, making them resemble tiny, irregular Tic-Tacs, which can then be mixed with salt.

To understand how their product would hold up in the real world, Diosady and his team used data gathered by a kind of salt tracking device—a small metal box slightly bigger than a pack of cards that could be packaged in salt shipments bound for shops in Kenya and Nigeria. The device captured snapshots of atmospheric conditions every 30 minutes over the course of the three-month journey from factory to shop. Using this data, they set large ovens to approximate various environments—from the tropical coast of Mombasa to the hot, dry atmosphere in Kano, Nigeria, to the temperate weather of Nairobi—and left Ziploc bags full of salt in them for months, finally testing them for stability.

Satisfied they’d created an adequately fortified, shelf-stable product, the researchers next had to find out if it would actually do the job they had designed it for: overcoming iron deficiency and preventing anemia. That process has taken even longer than developing the technology itself.

As Diosady and Mannar were getting their efforts under way, a group at India’s National Institute of Nutrition in Hyderabad developed a competing double-fortified salt, as did a research group at the Swiss Federal Institute of Technology. When the Swiss salt was tested in Morocco and Côte d’Ivoire, the results were mixed. One study showed levels of iron-deficiency anemia decreasing from 35% to 8% among Moroccan schoolchildren after 40 weeks, but another concluded that the encapsulation techniques still needed work.

In 2006, with funding from the Canadian government, the Indian state of Tamil Nadu began using Diosady’s salt formulation in lunches provided to 5 million schoolchildren. In 2008, a consortium of Swiss and Indian researchers began testing both Diosady’s formula and an alternative Swiss compound in 18 villages near Bangalore, some 200 miles west of where Mannar had grown up, to compare how well different forms of iron worked.

Iodine tends to react with impurities in salt, causing it to evaporate, so iodized salt becomes less effective over time. The Swiss salt, which contained iron in the form of ground-up ferric pyrophosphate, lost 44% of its iodine content in the first month of storage, and 86% after six months. But Diosady’s version performed just as well as regular iodized salt, losing just a fifth of its iodine content after six months. And in both kinds, the iron did its job: the Swiss formula cut the rate of anemia in the schoolchildren in half, and the Toronto version performed even better. The stearin coating, just a few microns thick, had proved to be up to the task. (Ferric pyrophosphate, used in the Swiss salt, is already white, eliminating the need for a coating, though the iron in it is less easily absorbed by the body.)

In 2014, results came back from another evaluation, conducted by research groups at Cornell and McGill universities. Diosady and Mannar’s DFS was given to 212 female tea pickers on an estate in Darjeeling, a lush green region in West Bengal, in the foothills of the Himalaya mountains. Of the 93 women who had too little iron in their blood at the outset of the study, 80% had normal levels by the end, about eight months later. Even better, their cognition and memory improved. A trial at 54 schools in the Indian state of Bihar in 2018, by a group from the University of Göttingen, found that DFS reduced anemia by 20%.

All the same, at least one major study has cast some doubts on the case for adding iron to salt. In a 2017 paper, Abhijit Banerjee, Sharon Barnhardt, and Esther Duflo reported that a trial they conducted across 400 villages in Bihar found “no evidence that either selling DFS or providing it for free has an economically meaningful or statistically significant impact on hemoglobin, anemia, physical health, cognition or mental health.”

That result carries some weight, since Banerjee and Duflo won the 2019 Nobel in economics for their work on evaluating the impact of development programs. In their paper, the researchers speculated that to avoid the risk of iron poisoning, the dose in the salt they were using might have been too small to overcome the iron deficiency.

Their study was one of 14 covered in a 2018 meta-analysis in the journal Advances in Nutrition, coauthored by Mannar. Overall, it found DFS effective at delivering iron and reducing anemia. More research may be needed. (Mannar says his salt tastes better than the formulation that Banerjee, Barnhardt, and Duflo studied.) But even if the benefits of iron-fortified salt aren’t yet certain, a lot of investment is going into making it more widely available.

The president of the Micronutrient Initiative was so pleased with Diosady and Mannar’s early work (and so keen to return to medical practice) that in 1994 he offered Mannar the presidency of the organization, which changed its name to Nutrition International in 2017. Mannar has overseen hundreds of fortification programs. He is partial to salt because it is cheap, and because rich and poor people eat similar amounts.

But Diosady wonders if even iodizing salt would be politically feasible today, despite its benefits, if it hadn’t already been done decades ago. Educated consumers have grown wary of tinkering with food and increasingly seek out the “natural.” Many tons of pink salt, which has a virginal, untouched aura, are mined in the Himalayas and exported. Diosady notes that even his own wife “is very leery of anything I bring from the lab.”

By 2016, the Food Safety and Standards Authority of India had finalized regulatory language governing the production of DFS. A manufacturing plant run by JVS Foods in Jaipur, in northwestern India, began to manufacture the premix at scale, in a process based on the one designed by Diosady and his team: JVS bought a few pieces of equipment and manufactured the rest, including extruders and coating machines. Mannar and researchers from the University of Toronto then persuaded salt processors to incorporate the premix. The plant’s initial output of 600 tons of premix a year was enough to supply over 40 million people. Diosady estimates that India now has capacity to produce DFS for 100 million people per year.

Still, whether DFS follows the path first trodden by iodized salt, from targeted intervention to universal condiment, depends in large part on whether commercial saltmakers can be enticed to begin manufacturing it at scale.

The state government of Uttar Pradesh, in India’s north, was the first to scale up distribution, beginning in late 2016. The salt was rolled out to 25 million consumers there through a network of 15,000 “fair price shops,” which sell government-subsidized staples. Other states followed: Madhya Pradesh in 2017 and Jharkhand in 2018. In September of that year, Prime Minister Narendra Modi plugged the salt in his weekly address to the nation.

Diosady estimates that it took $35 million, invested over 20 years, to develop the microencapsulation technology, test it in the field, and provide technical assistance to JVS to jump-start production. Funding came from various sources, including the Micronutrient Initiative, the Canadian government, the Bill and Melinda Gates Foundation, and the Tata Trusts, one of India’s largest philanthropies. Ratan Tata, the industrialist who heads the trusts, is a fortified-salt enthusiast, as is Bill Gates.

Still, whether DFS follows the path first trodden by iodized salt, from targeted intervention to universal condiment, depends in large part on whether commercial saltmakers can be enticed to begin manufacturing it at scale. That, argues Rajan Sankar, a program director for nutrition at the Tata Trusts and a former advisor to the Micronutrient Initiative, requires government intervention. India’s iodization push of the 1980s and 1990s succeeded because the government helped saltmakers buy modern equipment and provided free potassium iodate and technical support. If the public health authorities are serious about combating anemia, he asks, “What is the support [they] are ready to give?”

Mannar’s nephews now own and operate the family saltworks—he sold his own share decades ago. In the summer drying season, the flats still teem with laborers harvesting salt manually, but there is now a large, airy plant where salt is washed, ground, and iodized in huge metal vats. Sacks of salt, stacked a dozen high, await dispatch. But despite Mannar’s encouragement, the business doesn’t yet sell a double-fortified salt. “They would like to,” he says. But they are waiting for the market leaders to make the first move.

Deep Dive

Humans and technology

Building a more reliable supply chain

Rapidly advancing technologies are building the modern supply chain, making transparent, collaborative, and data-driven systems a reality.

Building a data-driven health-care ecosystem

Harnessing data to improve the equity, affordability, and quality of the health care system.

Let’s not make the same mistakes with AI that we made with social media

Social media’s unregulated evolution over the past decade holds a lot of lessons that apply directly to AI companies and technologies.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.