Protection on the cheap

In March, the shortage of face masks and other personal protective equipment (PPE) that health care professionals need to stay safe in the face of the pandemic reached the point where some resorted to cloak-and-dagger machinations to secure shipments from overseas. But a team from MIT came up with another solution: a quick, inexpensive technique for mass-producing disposable face shields, which medical staff can wear over their masked faces to extend the useful life of available PPE.

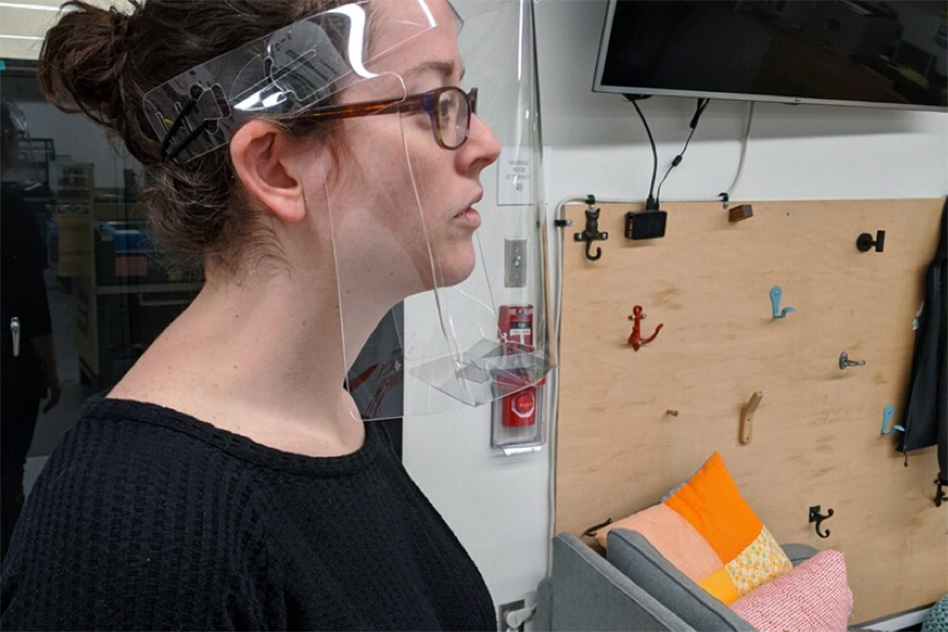

Martin Culpepper, SM ’97, PhD ’00, a professor of mechanical engineering and director of Project Manus, MIT’s effort to support maker activities, got the project under way in March. He and his team sought a shield that would be fast to produce, landing on a flat design that could be folded into a 3D structure as needed. As much of MIT’s campus life came to a halt, Culpepper started prototyping, using a laser cutter he had in his house. Aided by his children, he tested different low-cost materials and made the first 10 prototypes at home.

Next Elazer Edelman ’78, SM ’79, PhD ’84, director of MIT’s Institute for Medical Engineering and Science (IMES) and leader of the Institute’s PPE task force (see “A professor’s ‘new normal’ is anything but,” page 26), showed doctors and nurses at area hospitals how to store, assemble, and use the shields. Participants found that the shields were easy to put together and protected them well against splashes or aerosolized particles that might expose them to the virus. “The single greatest insecurity of a health-care provider is the thought that we will become infected and in doing so be unable to perform our duties or infect others,” Edelman says.

By late March, the team had shifted to mass manufacturing through a process known as die cutting. By mid-May, nearly 500,000 shields had been produced. “This process has been designed in such a way that there is the potential to ramp up to millions of face shields produced per day,” says Culpepper. “This could very quickly become a nationwide solution if traditional supply chains can’t keep up.”

MIT purchased the first 45,000 face shields to donate to hospitals in Boston and beyond; manufacturer Polymershapes also donated 60,000.

“This project was a great example of collaboration across MIT and the employment of mind-heart-hand,” Culpepper says. “When we reached out to others, they dropped everything to put their minds and hands to work helping us make this happen quickly.”

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.