A Simpler Recipe for Airplanes

Composite materials used in aircraft wings and fuselages are typically manufactured in very large, house-size ovens: multiple polymer layers are blasted with temperatures of up to 400 °C to form a solid, resilient material. With this approach, considerable energy is required to heat first the oven, then the gas within the oven, and finally the actual composite.

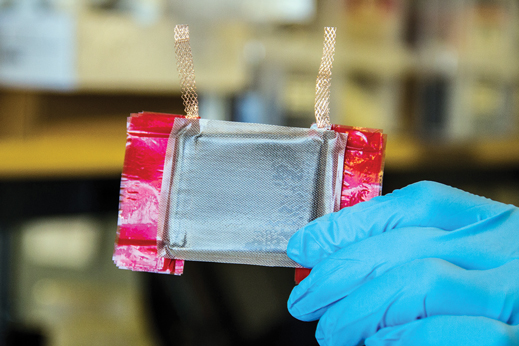

Aerospace engineers at MIT have now developed a carbon nanotube film that can accomplish the same end without these massive ovens. When wrapped over a multilayer polymer composite and connected to an electrical power source to heat it up, the film stimulates the polymer to solidify.

The group tested the film on a common carbon-fiber material used in aircraft components and found that it created a composite as strong as that manufactured in conventional ovens—using only 1 percent as much energy.

The new “out-of-oven” approach may offer a more direct energy-saving method to manufacture virtually any industrial composite, says Brian L. Wardle, SM ’95, PhD ’98, a professor of aeronautics and astronautics at MIT.

“Typically, if you’re going to cook a fuselage for an Airbus A350 or Boeing 787, you’ve got about a four-story oven that’s tens of millions of dollars in infrastructure that you don’t need,” Wardle says. “Our technique puts the heat where it is needed, in direct contact with the part being assembled. Think of it as a self-heating pizza … Instead of an oven, you just plug the pizza into the wall and it cooks itself.”

Wardle says the nanotube film, which is just a fraction as thick as the diameter of a human hair, is also incredibly light. After it has fused the underlying polymer layers, it meshes with the composite, adding negligible weight.

The team is working with industrial partners to scale up the technology so that the composites can be used to make airplane fuselages and wings.

The researchers, including MIT graduate students Jeonyoon Lee and Itai Stein and Seth Kessler ’99, SM ’00, PhD ’02, of the Metis Design Corporation, published their results in the journal ACS Applied Materials and Interfaces.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.