Building a Plane as if Assembling a Toy

Building anything from airplanes to bridges could soon become almost as simple as snapping together pieces of a child’s construction toy—and the result could be just as easy to disassemble later, so massive used parts wouldn’t have to be sent to a landfill or a scrap-metal plant.

Kenneth Cheung, SM ’07, PhD ’12, and Neil Gershenfeld, director of MIT’s Center for Bits and Atoms, have developed a system for assembling lightweight structures from thousands of tiny identical pieces based on a novel geometry. The work combines three fields of research, Gershenfeld says: fiber composites, cellular materials (those made with porous cells), and additive manufacturing (such as 3-D printing, in which structures are built by depositing material layer by layer).

The materials created this way are 10 times stiffer than existing ultralight materials of comparable weight. The individual parts could be mass-produced and then assembled by a crew of tiny robots that would crawl like insects over the surface of a growing structure, adding pieces one by one. By contrast, items made from conventional composites—now used in everything from golf clubs and tennis rackets to the components of Boeing’s new 787 jetliner—must be manufactured as a continuous unit. Large structures, such as airplane wings, require huge customized factories where fibers and resins can be wound and parts heat-cured as a whole.

The new technique allows much less material to carry a given load. Vehicles built this way could be lighter, significantly lowering fuel use and operating costs.

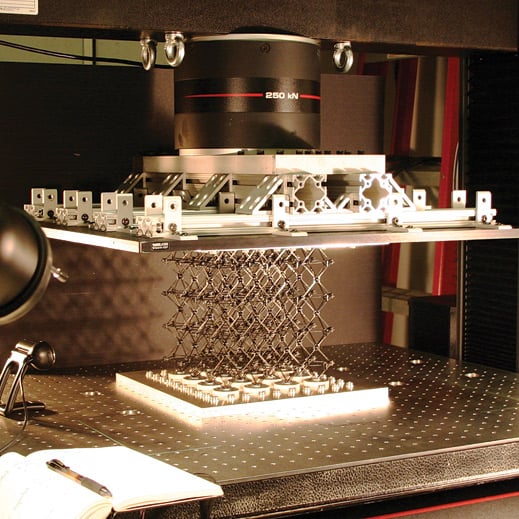

As an MIT postdoc, Cheung designed flat, cross-shaped composite pieces clipped into a cubic lattice of octahedral cells (dubbed a “cuboct”), similar to the crystal structure of the mineral perovskite. He and Gershenfeld show that the resulting structures behave like an elastic solid, with a stiffness equal to that of much heavier traditional structures, because forces are conveyed inside the pieces and distributed across the lattice.

While the individual components can be disassembled for repairs or recycling, there’s no risk that the structures will fall apart on their own, the researchers say. Like seatbelt buckles, the connections are designed to be strong in the direction of forces that might be applied in normal use, requiring pressure in an entirely different direction in order to be released.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.