GE’s New Natural-Gas Turbines Could Help Renewables

With the abundance of cheap natural gas propelling a shift away from coal for generating electricity, new gas turbine technology that GE announced yesterday could make it even more difficult for coal to compete. The technology could also help utilities integrate more renewable energy sources into their electricity mix.

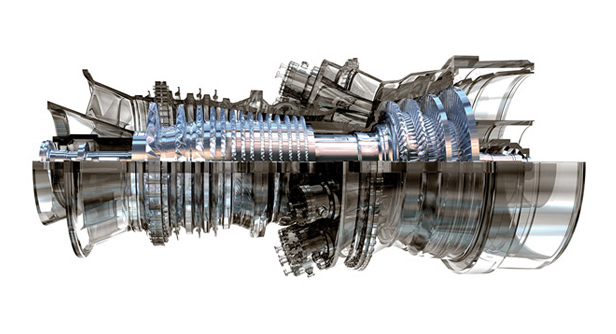

Conventional natural-gas power plants are generally either flexible or efficient. That is, some can quickly increase and decrease power output to meet spikes or lulls in electricity demand, while others are able to hum along steadily without using much natural gas but take hours to bring up to speed. GE’s gas turbines are meant to be efficient without sacrificing the ability to adjust power output in a hurry. Last year the company announced a version designed for use in Europe as well as China and other countries with power grids that operate at 50 hertz. Yesterday it announced a version for countries that use 60-hertz power, such as the United States, Japan, and nations in the Middle East. GE says it has $1.2 billion worth of orders for its new flexible gas turbines from Japan, Saudi Arabia, and the United States.

In the U.S., customers are installing the gas turbines to replace coal power. Japan is shifting to natural gas from nuclear power following the Fukushima power plant disaster last year. In Europe, much of the motivation for adopting GE’s new turbines could come from the promise of integrating renewable energy more efficiently into the grid. GE had previously announced a project that will combine the turbines with solar and wind power at a plant in Turkey.

GE’s turbines are efficient enough to help shave $3.5 million off the cost of operating a natural-gas combined-cycle power plant each year, says Eric Gebhardt, GE Energy’s vice president of thermal engineering. And because they are also far more flexible than conventional gas turbines in the way they can operate, they could help utilities that want to incorporate intermittent power sources like wind and solar tackle the problem of balancing electricity demand with supply (see “Improving demand forecasting for electric power to save fuel and reduce emissions”).

GE has adapted materials it uses in its jet engines to help enable the gas turbines to get up to speed in less than half an hour. It’s also improved its ability to precisely control temperatures within the turbine. Narrow channels cut into the materials deliver cooling gases to exactly where they’re needed to control the expansion rates of parts and ensure good seals. GE has also added ports for injecting fuel into different parts of the combustion chamber. That, along with new computer models describing the physics of combustion, makes it possible to optimize combustion temperatures.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.