Boeing Plans to Turbocharge Fuel-Efficient Flight

Since Boeing’s first jet airliner came to market more than five decades ago, the company has improved the fuel efficiency of its commercial planes by about 70 percent. But with growing pressure on airlines to save fuel costs and reduce greenhouse-gas emissions, the aircraft manufacturer now hopes to accelerate improvements by testing new technologies and designs at an earlier stage.

Emerging innovations are often slow to arrive on airport runways. Commercial planes are commonly in use for 20 years, and new models can take up to 10 years to bring to market. As a result, engineers are loath to rely on unproven technologies even when they’re needed to meet design goals, says David Akiyama, manager of the company’s new ecoDemonstrator program.

Under this program, Boeing will develop a new test bed airplane every year and use it to run a series of experimental flights. The first of these flights occurred over 45 days this summer above quiet cow pastures around Glasgow, Montana.

The ecoDemonstrator program will involve real-world tests of fuel-saving and noise-reducing technologies. Boeing itself is aiming for 20 percent improvements in fuel efficiency as it designs new aircraft models. Some technologies tested in the ecoDemonstrator flights could also be adopted in commercial planes already in use, Akiyama says.

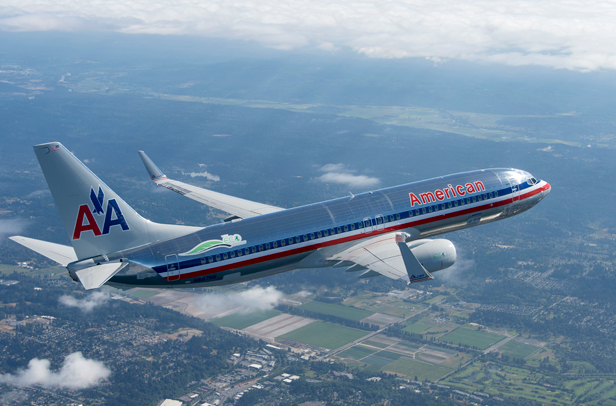

This year’s plane was a retrofitted Boeing 737-800, on loan from American Airlines. Rather than passenger seats, the cabin contained racks of computers and monitoring equipment.

The cargo space holds a regenerative fuel cell that creates hydrogen from water when energy is in excess and then turns it into electricity for the plane’s systems at times of peak demand. The fuel cell could eventually allow for lighter on-board generators in addition to reducing demand on the engines, says Akiyama.

Seven technologies and designs are being examined on the plane. Some, such as the fuel cell, are not quite commercially ready, but others are commonplace today.

The plane’s cockpit, for example, had a broadband satellite link and secure wireless network. This powers an iPad app built to supply real-time weather forecasts to pilots so they can plot more efficient routes around bad weather. Usually, pilots must give a storm a wider berth than necessary because they’re relying only on radar plus older forecasts given before takeoff. This kind of route optimization could save up to 5 percent of the fuel on a stormy flight, Akiyama says. Another novel feature, a structural design called an adaptive trailing wing edge, allows the plane to climb faster during takeoff, saving fuel and reducing noise.

For Boeing’s customers, new ideas that can reduce a plane’s overall fuel consumption, even by small amounts, are important. Today, fuel is often an airline’s top operating cost, and the growth of air travel worldwide is contributing to the sector’s rapidly expanding carbon footprint. This year, the European Union is implementing a cap on overall airline emissions and requiring airlines to either make carbon cuts or pay to purchase emissions permits. The U.S. industry is fighting to be exempted from the law, which would require their participation on all flights to and from Europe.

Boeing’s 2012 and 2013 ecoDemonstrator flights are partially funded by the U.S. Federal Aviation Administration. Next year, Akiyama expects to retrofit a wider-berth plane and work with the FAA to demonstrate a ceramic engine nozzle that’s lighter than the titanium used today and performs better under high temperatures—a key requirement as engines shrink and become more efficient.

Akiyama says the ecoDemonstrator program is unique for Boeing. It has real-world deadlines and safety demands, since human crews are on board. But the engineers can take on more technological risks than they could if they were working according to the usual product development cycle. “If I’m not failing every once in a while, it means we’re probably not pushing hard enough,” he says.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.