10 Breakthrough Technologies 2010

Emerging Technologies: 2010

Each year, Technology Review selects what it believes are the 10 most important emerging technologies. The winners are chosen based on the editors’ coverage of key fields. The question that we ask is simple: is the technology likely to change the world? Some of these changes are on the largest scale possible: better biofuels, more efficient solar cells, and green concrete all aim at tackling global warming in the years ahead. Other changes will be more local and involve how we use technology: for example, 3-D screens on mobile devices, new applications for cloud computing, and social television. And new ways to implant medical electronics and develop drugs for diseases will affect us on the most intimate level of all, with the promise of making our lives healthier.

10 Breakthrough Technologies

Solar Fuel

Designing the perfect renewable fuel.

Fuel for the future: Joule Biotechnologies' genetically engineered microörganisms can turn sunlight into ethanol or diesel. BOB O'CONNORWhen Noubar Afeyan, the CEO of Flagship Ventures in Cambridge, MA, set out to invent the ideal renewable fuel, he decided to eliminate the middleman. Biofuels ultimately come from carbon dioxide and water, so why persist in making them from biomass–corn or switchgrass or algae? “What we wanted to know,” Afeyan says, “is could we engineer a system that could convert carbon dioxide directly into any fuel that we wanted?”

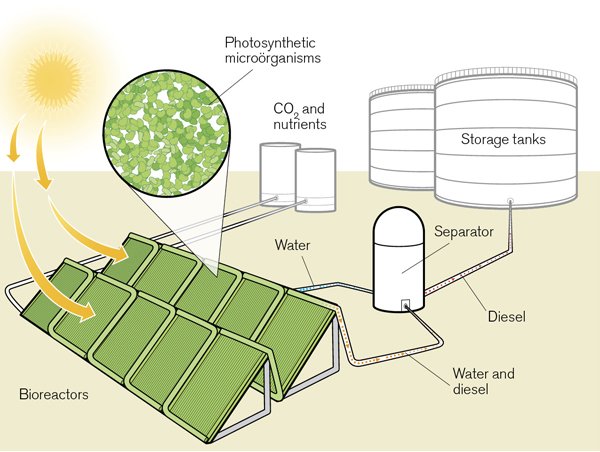

The answer seems to be yes, according to Joule Biotechnologies, the company that Afeyan founded (also in Cambridge) to design this new fuel. By manipulating and designing genes, Joule has created photosynthetic microörganisms that use sunlight to efficiently convert carbon dioxide into ethanol or diesel–the first time this has ever been done, the company says. Joule grows the microbes in photobioreactors that need no fresh water and occupy only a fraction of the land needed for biomass-based approaches. The creatures secrete fuel continuously, so it’s easy to collect. Lab tests and small trials lead Afeyan to estimate that the process will yield 100 times as much fuel per hectare as fermenting corn to produce ethanol, and 10 times as much as making it from sources such as agricultural waste. He says costs could be competitive with those of fossil fuels.

If Afeyan is right, biofuels could become an alternative to petroleum on a much broader scale than has ever seemed possible. The supply of conventional biofuels, such as those made from corn, is constrained by the vast amount of water and agricultural land needed to grow the plants they’re made from. And while advanced biofuels require less water and don’t need high-quality land, their potential is limited by the expensive, multistep processes needed to make them. As a result, the International Energy Agency estimates that in 2050, biodiesel and ethanol will meet only 26 percent of world demand for transportation fuel.

Joule’s bioengineers have equipped their microörganisms with a genetic switch that limits growth. The scientists allow them to multiply for only a couple of days before flipping that switch to divert the organisms’ energy from growth into fuel production. While other companies try to grow as much biomass as possible, Afeyan says, “I want to make as little biomass as I can.” In retrospect, the approach might seem obvious. Indeed, the startup Synthetic Genomics and an academic group at the BioTechnology Institute at the University of Minnesota are also working on making fuels directly from carbon dioxide. Joule hopes to succeed by developing both its organisms and its photobioreactor from scratch, so that they work perfectly together.

Oil farm: Arrays of bioreactors filled with Joule Biotechnologies' microörganisms absorb sunlight. Supplied with carbon dioxide and nutrients, the organisms use photosynthesis to produce diesel. As they secrete it, the diesel fraction circulates to a separator that extracts the fuel and sends it to storage tanks. BROWN BIRD DESIGNStill, it’s a risky strategy, since it departs from established processes. Usually, a startup sets out determined to do something novel, says James Collins, a professor of biomedical engineering at Boston University and a member of Joule’s scientific advisory board, “and it falls quickly back on trying to find something that works … an old thing that’s been well established.” Afeyan, however, has pushed the company to stay innovative. This summer, it will move beyond lab-scale tinkering; an outdoor pilot plant is currently under construction in Leander, TX.

As both a venture capitalist and a technologist–he received his PhD in chemical engineering from MIT in 1987–Afeyan is keenly aware of the challenges in demonstrating that a novel process can operate economically and make fuel in large volumes. To minimize the financial risks, he steered Joule toward a modular process that doesn’t require large and expensive demonstration plants.

“I’m not saying it’s easy or around the corner, because I’ve done this for a long time,” Afeyan says. But he does believe that Joule is onto something big: a renewable fuel that could compete with fossil fuels on both cost and scale. He says, “We have the elements of a potentially transformative technology.”

Real-Time Search

Social networking is changing the way we find information.

The real-time man: Google's Amit Singhal is mining social networks to generate up-to-the-second search results. TOBY BURDITTHow do you parse a tweet? Five years ago, that question would have been gibberish. Today, it’s perfectly sensible, and it’s at the front of Amit Singhal’s mind. Singhal is leading Google’s quest to incorporate new data into search results in real time by tracking and ranking updates to online content–particularly the thousands of messages that course through social networks every second.

Real-time search is a response to a fundamental shift in the way people use the Web. People used to visit a page, click a link, and visit another page. Now they spend a lot of time monitoring streams of data–tweets, status updates, headlines–from services like Facebook and Twitter, as well as from blogs and news outlets.

Ephemeral info-nuggets are the Web’s new currency, and sifting through them for useful information is a challenge for search engines. Its most daunting aspect, according to Singhal, is not collecting the data. Facebook and Twitter are happy to sell access to their data feeds–or “fire hoses,” as they call them–directly to search providers; the information pours straight into Google’s computers.

What’s really hard about real-time search is figuring out the meaning and value of those fleeting bits of information. The challenge goes beyond filtering out spam, though that’s an important part of it. People who search real-time data want the same quality, authority, and relevance that they expect when they perform traditional Web searches. Nobody wants to drink straight from a fire hose.

Google dominates traditional search by meticulously tracking links to a page and other signals of its value as they accumulate over time. But for real-time search, this doesn’t work. Social-networking messages can lose their value within minutes of being written. Google has to gauge their worth in seconds, or even microseconds.

Google is notoriously tight-lipped about its search algorithms, but Singhal explains a few of the variables the company uses to analyze what he calls “chatter.” Some are straightforward. A Twitter user who attracts many followers, and whose tweets are often “retweeted” by other users, can generally be assumed to have more authority. Similarly, Facebook users gain authority as their friends multiply, particularly if those friends also have many friends.

Other signals are more subtle. A sudden spike in the prevalence of a word in a message stream–earthquake, say–may indicate an important event. If a message on a commonly discussed topic includes unusual phrasing, that may signal new information or a fresh insight. Google, says Singhal, continuously scans for shifts in language and other deviations from predicted behavior.

The company is also working to connect message content to the geolocation data that’s transmitted by smart phones and other mobile computers, or broadcast through services like Foursquare. The location of someone sending a message can matter a great deal. If you know that a person tweeting about an earthquake is close to the epicenter, chances are those tweets will be more valuable than those of someone hundreds of miles away.

Singhal’s view of real-time search is very much in line with Google’s strategy: distilling from a welter of data the few pieces of content that are most relevant to an individual searcher at a particular point in time. Other search providers, including Google’s arch rival, Microsoft, are taking a more radical view.

Sean Suchter, who runs Microsoft’s Search Technology Center in Mountain View, CA, doesn’t like the term real-time search, which he considers too limiting. He thinks Microsoft’s Bing search engine should not just filter data flowing from social networks but become an extension of them.

Ultimately, says Suchter, one-on-one conversations will take place within Bing, triggered by the keywords people enter. Real-time search, he predicts, will be so different from what came before that it will erase Google’s long-standing advantages. “History doesn’t matter here,” he says. After a pause, he adds, “We’re going to wipe the floor with them.”

Amit Singhal has heard such threats before, and so far they haven’t amounted to much. But even he admits that real-time search comes as close to marking “a radical break” in the history of search as anything he’s seen. Keeping Google on top in the age of chatter may prove to be Singhal’s toughest test.

Mobile 3-D

Smart phones will take 3-D mainstream.

3-D on the go: Released in South Korea in March, Samsung's W960 mobile phone comes with 3-D video content, generated by Dynamic Digital Depth, that can be viewed without special glasses. Dynamic Digital Depth expects that its software to convert 2-D games to 3-D on the fly will be built into phones within the next two years. BRYAN CHRISTIE DESIGNThe Samsung B710 phone looks like a typical smart phone, but something unexpected happens when the screen is moved from a vertical to a horizontal orientation: the image jumps from 2-D to 3-D. The technology that produces this perception of depth is the work of Julien Flack, CTO of Dynamic Digital Depth, who has spent more than a decade perfecting software that can convert 2-D content to 3-D in real time. It could help solve the biggest problem with 3-D: the need for special glasses that deliver a separate image to each eye.

Flack’s software synthesizes 3-D scenes from existing 2-D video by estimating the depth of objects using various cues; a band of sky at the top of a frame probably belongs in the far background, for example. It then creates pairs of slightly different images that the viewer’s brain combines to produce the sensation of depth.

The technology can be used with the much-hyped 3-D televisions announced in January (which require glasses), but its biggest impact will be as a way to create content for mobile devices with autostereoscopic 3-D displays, which work by directing light to deliver different versions of an image directly to each of a viewer’s eyes. The effect works best over a narrow range of viewing angles, so it is ill suited to television or cinema screens. But phones are generally used by one person at a time and are easily held at the optimum angle. That’s why mobile multimedia devices are likely to win the race to bring 3-D into the mainstream.

Powered by Flack’s software, Dynamic Digital Depth has become an early leader in mobile 3-D. The software was built into the B710, which Samsung released in South Korea in 2007, and Samsung has licensed 3-D content generated by Dynamic Digital Depth for its latest 3-D phone, the W960, released in March. Research firm DisplaySearch recently predicted that by 2018 there will be 71 million such devices worldwide.

The most exciting area for Flack right now is games. Hundreds of games actually simulate 3-D spaces internally to handle mechanics such as the path of a missile, and then convert those 3-D spaces into 2-D to display to the player. With his technology, he says, the 3-D geometry “available inside the game itself” can be made accessible to the display. DDD has already released software that converts games to 3-D on PCs and expects to have similar software running on mobile devices in the next year or two.

It’s applications like mobile games and video that will drive the widespread adoption of 3-D screens. And that, in turn, could lay the groundwork for a new generation of surprising interfaces and applications, just as large 2-D screens on mobile devices spawned developments such as touch-based interfaces and augmented reality.

Engineered Stem Cells

Mimicking human disease in a dish.

The cell factory: James Thomson (above) and Junying Yu first transformed adult cells into stem cells called iPS cells in 2007. KEVIN MIYAZAKIThe small plastic vial in James Thomson’s hand contains more than 1.5 billion carefully coddled heart cells grown at Cellular Dynamics, a startup based in Madison, WI. They are derived from a new type of stem cell that Thomson, a cofounder of the company, hopes will improve our models of human diseases and transform the way drugs are developed and tested.

Thomson, director of regenerative biology at the Morgridge Institute at the University of Wisconsin, first isolated human embryonic stem cells in 1998. Isolating these cells, which are capable of maturing into any other type of cell, marked a landmark in biology–but a controversial one, since the process destroys a human embryo. A decade later, Thomson and Junying Yu, then a Wisconsin postdoc, reached another milestone: they developed a way to make stem cells from adult cells by adding just four genes that are normally active only in embryos. (Japanese researcher Shinya Yamanaka simultaneously published a similar approach.) Dubbed induced pluripotent stem cells (iPS cells), they have the two defining characteristics of embryonic stem cells: they can reproduce themselves many times over, and they can develop into any cell type in the human body. Because no human embryos are used to create them, iPS cells solve two problems that had long plagued researchers: political protest and shortages of material.

Much of the excitement over iPS cells, and stem cells in general, arises from the possibility that they could replace damaged or diseased tissue. But Thomson thinks their most important contribution will be to provide an unprecedented window on human development and disease. Scientists can create stem cells from the adult cells of people with different disorders, such as diabetes, and induce them to differentiate into the types of cells damaged by the disease. This could allow researchers to watch the disease as it unfolds and trace the molecular processes that have gone awry.

In the nearer term, iPS cells may revolutionize toxicity testing for drugs. The cells are “the first unlimited source of any type of human tissue,” says Thomson, who founded Cellular Dynamics to put stem cells to practical use. The company sells heart muscle cells derived from its iPS cells to pharmaceutical giants such as Roche, which are using them to screen experimental drugs for harmful side effects. Thomson hopes those cells will help uncover problems early in the drug development process, saving billions of dollars on research and testing. For instance, since the iPS-derived heart cells will beat in a dish, scientists should be able to detect which drugs alter the heart’s rhythm. Scientists can also use the cells to study how the heart functions at a molecular level. And the company is developing other cell types, including brain and liver cells. The latter are of particular interest to pharmaceutical researchers, since drug toxicity often shows up in the liver. “Having a model that would predict toxicity before going into humans is incredibly valuable,” says Chris Parker, vice president and chief commercial officer of Cellular Dynamics.

By generating iPS cells from people with diverse ethnic backgrounds and genetic conditions, and from those who have reacted poorly to certain drugs, scientists can also gain a better picture of how compounds will affect different people. Thomson and others have already created iPS cells from people with ALS, Down syndrome, and spinal muscular atrophy, among other disorders. While it’s not yet clear how well those cells reflect the specific diseases, early research is promising. If it succeeds, researchers hope to use iPS cells to study other disorders and develop drugs to treat them. “That’s the thing that would fundamentally change the way drug development happens,” says Kyle Kolaja, director of early safety and investigative toxicology at Roche, which has partnered with Cellular Dynamics.

The last decade brought many difficult years for Thomson. His work on embryonic stem cells was a breakthrough, but it also brought intense controversy and media attention, turning him somewhat reclusive. With the rise of iPS cells and Cellular Dynamics, Thomson is beginning to come back to the limelight. “I think the legacy of embryonic stem cells will be that they gave rise to iPS cells,” he says. “These cells will be used in creative ways we can’t even imagine.”

Light-Trapping Photovoltaics

Nanoparticles boost solar power’s prospects.

Solar spheres: By depositing nanoparticles made of silver on thin-film photovoltaic cells, Kylie Catchpole increases the cells' efficiency, which could make solar power more competitive. MEGHAN PETERSENIn 1995, finishing her undergraduate degree in physics, Kylie Catchpole decided to take a risk on a field that was nearly moribund: photovoltaics. “There was a sense that I might have difficulty ever being employed,” she recalls. But her gamble paid off. In 2006 Catchpole, then a postdoc, discovered something that opened the door to making thin-film solar cells significantly more efficient at converting light into electricity. It’s an advance that could help make solar power more competitive with fossil fuels.

Thin-film solar cells, which are made from semiconductor materials like amorphous silicon or cadmium telluride, are cheaper to produce than conventional solar cells, which are made from relatively thick and expensive crystalline wafers of silicon. But they are also less efficient, because if a cell is thinner than the wavelength of incoming light is long, that light is less likely to be absorbed and converted. At just a few micrometers thick, thin-film cells only weakly absorb wavelengths in the near-infrared part of the spectrum; that energy is lost. The result is that thin-film photovoltaics convert 8 to 12 percent of incoming light to electricity, versus 14 to 19 percent for crystalline silicon. Thus, larger installations are required in order to produce the same amount of electricity, limiting the number of places the technology can be used.

Catchpole, who is now a research fellow at the Australian National University in Canberra, began work on this problem in 2002 at the University of New South Wales in Sydney. “It was a case of ‘start at the beginning: can you think of a completely different way to make a solar cell?’ ” she says. “One of the things I came across was plasmonics–looking at the strange optical properties of metals.”

Plasmons are a type of wave that moves through the electrons at the surface of a metal when they are excited by incident light. Others had tried harnessing plasmonic effects to make conventional silicon photovoltaics more efficient, but no one had tried it with thin-film solar cells. Catchpole found that nanoparticles of silver she deposited on the surface of a thin-film silicon solar cell did not reflect back light that fell directly onto them, as would happen with a mirror. Instead, plasmons that formed at the particles’ surface deflected the photons so that they bounced back and forth within the cell, allowing longer wavelengths to be absorbed.

Catchpole’s experimental devices produce 30 percent more electrical current than conventional thin-film silicon cells. If Catchpole can integrate her nanoparticle technology with the processes used to mass-produce thin films commercially, it could shift the balance of technology used in solar cells. Thin-film photovoltaics could not only gain market share (they currently have just 30 percent of the market in the United States) but sustain growth in the solar industry overall.

Thus far, silicon has been losing out to cadmium telluride as the material of choice for thin-film solar cells. (First Solar, the market leader, is planning gigawatt-scale solar farms that will use cadmium telluride thin-film technology to deliver as much electricity as conventional power stations.) But tellurium is a rare material, and experts question whether the supply will support such grand ambitions. “There just isn’t enough tellurium to make a substantial difference to the way the world’s energy is produced,” says Catchpole. “Silicon is the way to go.”

Catchpole has been approached by companies, but she wants to refine the technology further before commercializing it. Meanwhile, researchers at Swinburne University of Technology in Melbourne are collaborating with Suntech Power, one of the world’s largest manufacturers of silicon solar cells, on plasmonic thin-film silicon cells of their own. The company’s plasmonic photovoltaics are expected to be ready for production within four years.

Social TV

Relying on relationships to rebuild TV audiences.

The viewership for live television broadcasts has generally been declining for years. But something surprising is happening: events such as the winter Olympics and the Grammys are drawing more viewers and more buzz. The rebound is happening at least in part because of new viewing habits: while people watch, they are using smart phones or laptops to swap texts, tweets, and status updates about celebrities, characters, and even commercials.

Marie-José Montpetit, an invited scientist at MIT’s Research Lab for Electronics, has been working for several years on social TV–a way to seamlessly combine the social networks that are boosting TV ratings with the more passive experience of traditional TV viewing. Her goal is to make watching television something that viewers in different places can share and discuss–and to make it easier to find something to watch.

Carriers, networks, and content producers hope that making it easier for viewers to link up with friends will help them hold on to their audiences rather than losing them to services like Hulu, which stream shows over the Internet. And opening TV to social networking could make it easier for companies to provide personalized programming.

Many developers are working on ways to let people share the viewing experience over broadband connections or through set-top boxes; indeed, cable companies and other broadband video providers have sponsored small trials of various interactive TV services around the world for more than 20 years. But most of the systems were even clumsier than the combination of laptop and large-screen TV that today’s viewers have kludged together. Montpetit wants to unite different communication systems–especially cellular and broadband services–to create an elegant user experience. She’s been sharing ideas about that sort of system with BT, which provides broadband connections to 15 million people in the United Kingdom and Ireland, including nearly a half-million digital-TV subscribers.

Though BT won’t comment on what form its social-TV system might take, Montpetit and her students at the MIT Media Lab demonstrated an intriguing prototype last year. A central database aggregates video from online sources like YouTube, shares user-specified data with social networks, delivers video to the user’s TV, and lets users and the people in their networks send comments and ratings back and forth via an iPhone app. It avoids using the TV screen for messages, something that has proved irritating to consumers who don’t want clunky text obscuring the pictures on their 52-inch HDTVs. The app also allows the user to tell the network what program to show on his or her set. For instance, if a friend suggests a show and the owner agrees, that show will pop up at the appointed time. In February, Montpetit and her students presented a refined version of this system to BT. Jeff Patmore, who works with Montpetit as head of strategic university research at BT, says such a system could be rolled out this year, although he declines to confirm any plans. But Montpetit anxiously awaits U.S. deployment of social TV: her daughter, with whom she watches certain shows, heads off to college next fall. Engineering and business issues aside, she wants social TV to help friends and family stay connected, even as they move apart.

Green Concrete

Storing carbon dioxide in cement. NATO WELTON

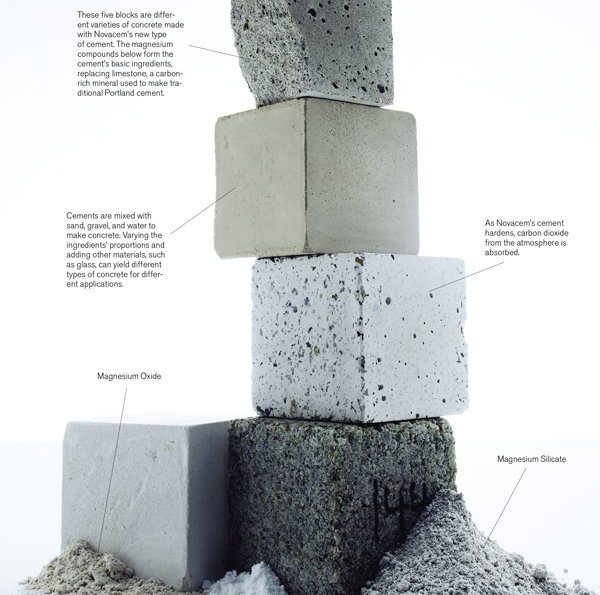

NATO WELTONMaking cement for concrete involves heating pulverized limestone, clay, and sand to 1,450 °C with a fuel such as coal or natural gas. The process generates a lot of carbon dioxide: making one metric ton of commonly used Portland cement releases 650 to 920 kilograms of it. The 2.8 billion metric tons of cement produced worldwide in 2009 contributed about 5 percent of all carbon dioxide emissions. Nikolaos Vlasopoulos, chief scientist at London-based startup Novacem, is trying to eliminate those emissions with a cement that absorbs more carbon dioxide than is released during its manufacture. It locks away as much as 100 kilograms of the greenhouse gas per ton.

Vlasopoulos discovered the recipe for Novacem’s cement as a grad student at Imperial College London. “I was investigating cements produced by mixing magnesium oxides with Portland cement,” he says. But when he added water to the magnesium compounds without any Portland in the mix, he found he could still make a solid-setting cement that didn’t rely on carbon-rich limestone. And as it hardened, atmospheric carbon dioxide reacted with the magnesium to make carbonates that strengthened the cement while trapping the gas. Novacem is now refining the formula so that the product’s mechanical performance will equal that of Portland cement. That work, says Vlasopoulos, should be done “within a year.”

Other startups are also trying to reduce cement’s carbon footprint, including Calera in Los Gatos, CA, which has received about $50 million in venture investment. However, Calera’s cements are currently intended to be additives to Portland cement rather than a replacement like Novacem’s, says Franz-Josef Ulm, director of the Concrete Sustainability Hub at MIT. Novacem could thus have the edge in reducing emissions, but all the startups face the challenge of scaling their technology up to industrial levels. Still, Ulm says, this doesn’t mean a company must displace billions of tons of Portland cement to be successful; it can begin by exploiting niche areas in specialized construction. If Novacem can produce 500,000 tons a year, Vlasopoulos believes, it can match the price of Portland cement.

Even getting that far will be tough. “They are introducing a very new material to a very conservative industry,” says Hamlin Jennings, a professor in the Department of Civil and Environmental Engineering at Northwestern University. “There will be questions.” Novacem will start trying to persuade the industry by working with Laing O’Rourke, the largest privately owned construction company in the U.K. In 2011, with $1.5 million in cash from the Royal Society and others, Novacem is scheduled to begin building a new pilot plant to make its newly formulated cement.

Implantable Electronics

Dissolvable devices make better medical implants.Implanted under the skin, an array of light-emitting diodes could signal the concentration in the blood of biomarkers such as insulin. Over time, the array will dissolve away, eliminating the need for surgery to remove the implant. Flexible silicon electronics (inset) are held in place with a silk film. Incorporating antibodies or enzymes into the film will allow devices to detect biomarkers.Bryan Christie Design The next generation of implantable medical devices will rely on a high-tech material forged not in the foundry but in the belly of a worm. Tufts University biomedical engineer Fiorenzo Omenetto is using silk as the basis for implantable optical and electronic devices that will act like a combination vital-sign monitor, blood test, imaging center, and pharmacy–and will safely break down when no longer needed.

Implanted electronics could provide a clearer picture of what’s going on inside the body to help monitor chronic diseases or progress after surgery, but biocompatibility issues restrict their use. Many materials commonly used in electronics cause immune reactions when implanted. And in most cases today’s implantable devices must be surgically replaced or removed at some point, so it’s only worth using an implant for critical devices such as pacemakers. Silk, however, is biodegradable and soft; it carries light like optical glass; and while it can’t be made into a transistor or an electrical wire, it can serve as a mechanical support for arrays of electrically active devices, allowing them to sit right on top of biological tissues without causing irritation. Depending on how it’s processed, silk can be made to break down inside the body almost instantly or to persist for years. And it can be used to store delicate molecules like enzymes for a long time.

Omenetto began working with silk three years ago, when David Kaplan, a biomedical engineer across the hall, asked for help making the material into complex scaffolds for growing new tissues. He boils silkworm cocoons and purifies the resulting solution to create his master ingredient, a water-based solution of the silk protein called fibroin. This solution can be poured into molds to make structures whose features are as small as 10 nanometers across. Omenetto has molded it into a wide variety of optical devices, such as lenses, mirrors, prisms, and optical fibers, all of which could be used to direct light to and from biosensors implanted in the body. Mixing antibodies or enzymes into the silk solution before molding it results in devices that could someday be used to sense low concentrations of just about any biological molecule, from glucose to tumor markers.

Collaborating with Kaplan and materials scientist John Rogers at the University of Illinois at Urbana-Champaign, Omenetto has produced implants that combine silk with flexible silicon electronics. For instance, the group has used silk films to hold in place arrays of tiny silicon transistors and LEDs–a possible basis for implantable devices that will help identify the concentration of disease markers. The researchers have shown that the devices function fine in small animals, with no evidence of scarring or immune response. The silk dissolves, leaving behind a small amount of silicon and other materials used in the circuits.

Another device uses silk as a substrate for a metal electrode mesh designed to replace spike-like electrodes used on the surface of the brain to diagnose and treat conditions such as epilepsy. When doused with saline solution, the silk wraps the mesh around the surface of the brain (even tucking it into the creases), helping the electrodes measure neural activity more precisely. The silk-based electrodes will probably be the first of the group’s devices to be tested in people, perhaps in two to three years.

Omenetto sees other possibilities further in the future: for example, a silk optical fiber could transmit light from an LED array to an implanted silk sensor, which would change color to indicate that a cancer has come back. The device might then release a precisely calibrated dose of a drug. A second silk fiber could transmit that information to the surface of the patient’s skin, where the output might be read by a cell phone. All the components for making such things exist, Omenetto says. Once the pieces are brought together, a little silk will help save lives.

Dual-Action Antibodies

Fighting cancer more efficiently.

Two for the price of one: Antibody drugs work by binding to antigens such as extracellular proteins or receptors on a cell's surface, blocking their ability to function or targeting them for destruction by the immune system. Genentech's new antibodies can bind to two different antigens, potentially reducing the number of drugs required to treat diseases. The antibody colored yellow can bind only to a receptor on the surface of a cancer cell. The green-colored antibody can bind only to an extracellular protein that promotes tumor growth. The new antibody (red) can bind to both the surface receptor and the extracellular protein. BRYAN CHRISTIE DESIGNAt Genentech’s sprawling headquarters south of San Francisco, senior scientist Germaine Fuh has been genetically redesigning two of the company’s most lucrative cancer drugs. One, Herceptin, is a monoclonal antibody that shuts down HER2, a growth accelerator in about 20 percent of breast tumors. The other, Avastin, is an antibody that blocks a protein that stimulates the formation of tumor-feeding blood vessels. Last year the drugs had combined sales of $11 billion; a full course of Herceptin at wholesale costs about $43,000, while treating a breast cancer patient with a full course of Avastin costs about $55,000. Fuh’s goal: to show she can provide greater benefit for people fighting breast cancer by combining the action of the antibodies in one molecule. Last year, she and her coworkers showed that a modified version of the Herceptin antibody not only shut down the HER2 receptor in mice but also locked onto VEGF, Avastin’s target.

Designing such “dual-specific” antibodies could help solve a major problem with chemotherapy drugs: cancer cells can become resistant to them, mutating in ways that allow them to dodge the medication’s action. Doctors often mix various chemotherapy drugs in an effort to kill cancers before they can exploit this escape mechanism. Having a single drug that can hit the cancer from multiple directions would simplify treatment.

A single monoclonal antibody that could do the work of two is also attractive from a business perspective. It might cost half as much to manufacture as two separate antibodies, and the path to regulatory approval might also be shorter and less expensive, involving one set of clinical trials instead of multiple trials for two separate drugs in various dosage combinations. Genentech has started trials to determine whether Herceptin and Avastin together will fight breast cancer better than either used alone, but the cost of such studies is a big disincentive to doing them regularly.

Fuh’s research into whether one antibody drug could be redesigned to do the work of two began six years ago. An antibody, one of the immune system’s most robust weapons, is a Y-shaped protein about 10 nanometers long. At the tip of each branch is an active site, which grabs a specific molecule on an invading microbe or cancer cell. Swarms of antibodies disable the invader, marking it for destruction by white blood cells or other immune molecules.

Fuh notes that many mammalian antibodies have some ability to bind to a second antigen, but typically they do so weakly. Her goal was to exploit this ability while making both bonds tight and functional. Fuh’s team induced subtle mutations at the tips of Herceptin and screened 10 billion mutant clones for activity against VEGF. They netted several candidates–including one with active sites that could bind to both HER2 and VEGF strongly enough to limit tumor growth.

Genentech, now a wholly owned subsidiary of Swiss pharmaceutical giant Roche, is using this technique to develop another dual-specific drug, which may soon be ready for clinical trials. Fuh won’t disclose the details of what the drug is for and will only say, “Right now, we are very close.”

Meanwhile, her experiments have fueled interest in the overall potential of such drugs. “The two-for-one drug concept is important, especially for indications like cancer,” says Carlos Barbas III, a professor of molecular biology at the Scripps Research Institute in La Jolla, CA. Barbas is the founder of CovX, a company working on a different approach to making dual-specific antibodies (Pfizer acquired it in 2008). Despite the competition, he praises the accomplishment of the Genentech team as “a beautiful piece of antibody engineering.”

The implications of Fuh’s research are indeed far-reaching. If the concept proves successful, antibodies that stick to two targets might be used to treat infectious diseases as well as cancer–offering the promise of drugs that work better and cost less.

Cloud Programming

A new language will improve online applications.

Joseph Hellerstein wants cloud programmers to reach new heights. TOBY BURDITTCloud computing offers the promise of virtually unlimited processing and storage power, courtesy of vast data centers run by companies like Amazon and Google. But programmers don’t know how best to exploit this power.

Today, many developers are converting existing programs to run on clouds, rather than creating new types of applications that could work nowhere else. And they are held back by difficulties in keeping track of data and getting reliable information about what’s going on across a cloud. If programmers could solve those problems, they could start to really take advantage of what’s possible with a cloud. For example, an online music retailer could monitor popular social-media feeds; if a singer suddenly became a hot topic, advertising and special offers across the retailer’s site could be instantly reconfigured to make the most of the spike in interest.

At the University of California, Berkeley, Joseph Hellerstein thinks he can make it much easier to write complex cloud applications by developing software that takes over the job of tracking data and keeping tabs on what’s happening. His big idea is to modify database programming languages so that they can be used to quickly build any sort of application in the cloud–social networks, communication tools, games, and more. Such languages have been refined over the years to hide the complexities of shuffling information in and out of large databases. If one could be made cloud-friendly, programmers could just think about the results they want, rather than micromanaging data.

The challenge is that these languages process data in static batches. They can’t process data that is constantly changing, such as readings from a network of sensors. The solution, Hellerstein explains, is to build into the language the notion that data can be dynamic, changing as it’s being processed. This sense of time enables a program to make provisions for data that might be arriving later–or never.

The result is called Bloom. So far, Hellerstein’s group has used the Bloom language and its predecessors to quickly rebuild and add major features to popular cloud tools such as Hadoop, a platform used to manipulate very large amounts of data. By lowering the complexity barrier, these languages should increase the number of developers willing to tackle cloud programming, resulting in a wave of ideas for new types of powerful applications.

Hellerstein’s group is getting Bloom ready for a release in late 2010. They and others are also working on demonstrating how the techniques can be used for real-time applications such as online multiplayer games, or to watch for the warning signs of an earthquake or tsunami.