New Ink Opens the Door to3-D-Printed Radar

We can now add radar technology to the growing list of odd but useful things that can be made with 3-D printing.

Printing the electronics in sophisticated radar systems onto sheets of plastic would make the systems both cheaper and more versatile. This would have obvious military benefits but also many potential civilian applications, such as weather-monitoring radar and self-driving vehicles. One major challenge in printing electronics capable of dealing with high-frequency radio waves is developing novel “inks” with the right electrical properties.

Researchers at a Raytheon-sponsored lab at the University of Massachusetts, Lowell, say they have a solution: a new “functional ink” they have used to print devices that can be tuned to generate or detect radio waves of specific frequencies, an essential capability of radar. Radar systems work by transmitting radio waves and then detecting the signals that return after the waves hit an object in their path.

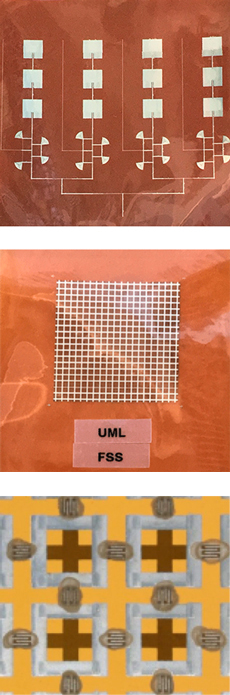

The new ink is key to printing a specific type of capacitor called a voltage-variable capacitor, or varactor. The researchers believe theirs is the first all-printed varactor, an essential electrical component of certain tunable electronic devices used in military radar systems as well as automobile collision-avoidance systems and cell-phone towers.

One of those devices, called a phase shifter, is needed to electronically steer the beam of a so-called phased-array radar system. Another device now printable thanks to the new ink is a frequency-selective surface—essentially a filter that can block specific frequencies of electromagnetic radiation or allow them to pass through. Such filters prevent unwanted radiation from disrupting a radar system. They can also be used to do things like shield a particular environment, such as a hospital.

The ability to print these systems could eventually lead to much cheaper and faster manufacturing processes than the ones used today, says Christopher McCarroll, who co-directs the Raytheon UMass-Lowell Research Institute. The bottleneck has been that high-performing electronic devices generally rely on materials requiring high-temperature manufacturing, which is not compatible with plastic.

Researchers have already developed conductive inks, often containing metal nanoparticles, that can be processed at relatively low temperatures (see “Printing Batteries”). Inks that would yield tunable devices for radar must contain materials with certain electrical properties that can be adjusted by applying voltage.

The ink the Raytheon and UMass-Lowell researchers came up with is made of tiny particles of such material suspended in a thermoplastic polymer. The new ink can be printed and cured at temperatures low enough to be compatible with certain plastics.

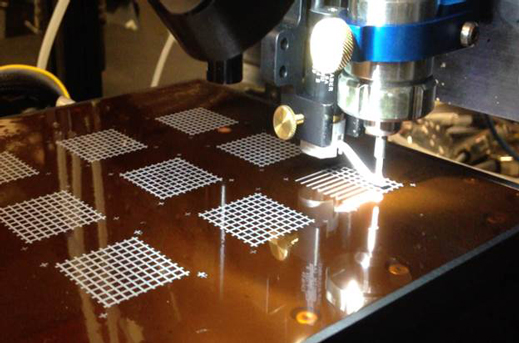

To make the two devices, the group currently uses an aerosol-jet printer, which employs streams of gas to precisely deposit conductive ink made of silver, and another printer that relies on tiny vibrations to dispense the new ink.

The researchers are still experimenting with their materials and device designs. They are also exploring ways to combine printed devices with the high-powered computer chips that are essential to radar systems. McCarroll says the “dream” is to print the whole radar system, but the near-term goal is to develop efficient processes for building systems out of both printed components and those made with conventional means.

Keep Reading

Most Popular

Large language models can do jaw-dropping things. But nobody knows exactly why.

And that's a problem. Figuring it out is one of the biggest scientific puzzles of our time and a crucial step towards controlling more powerful future models.

The problem with plug-in hybrids? Their drivers.

Plug-in hybrids are often sold as a transition to EVs, but new data from Europe shows we’re still underestimating the emissions they produce.

How scientists traced a mysterious covid case back to six toilets

When wastewater surveillance turns into a hunt for a single infected individual, the ethics get tricky.

Google DeepMind’s new generative model makes Super Mario–like games from scratch

Genie learns how to control games by watching hours and hours of video. It could help train next-gen robots too.

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.